Case of grinding and polishing solutions for HVOF coating

What is HVOF coating?

High Velocity Oxygen Fuel (HVOF) coating is a thermal spray process in which a fuel and oxygen are mixed, fed into a combustion chamber, and ignited. The gas produced in the combustion chamber has an extremely high temperature and pressure and is ejected through a nozzle at supersonic speeds. Powder is injected into the high velocity gas stream and propelled at the substrate to be coated. The result is a coating that has a low porosity and a high bond strength to the substrate material, which provides it with wear and / or corrosion resistance.Recently we recieve the inquiry about HVOF Coating grinding and polishing, let’s see the requirements of customer.

For HVOF coating ,Moresuperhard have many customers in different areas, such as India, Indonesia, Singapore, Saudi Arabia, UAE, Norway, Canada, Turkey, Qatar,UK…

Moresuperhard can provide a series of grinding solutions of thermal spraying coating range from diamond belts to diamond/cbn wheels . Any question of hvof or plasma spray coatings you can feel free to discuss with us.

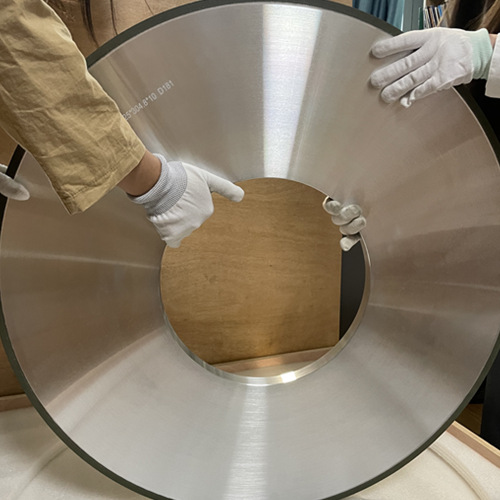

Moresuperhard have much experience for this area’s grinding and polishing, can provide not only diamond /CBN wheels, but also diamond/CBN belts, hand pads as well as grinding and polishing discs. Sizes widely used are D400,D500,D600,D750,D900,D915,D1050.

In India, Justright Oilfield Services used our D900-T75 HVOF diamond wheel. Also, we have other companies that do not want us to provide their company information.

Canada bought all sizes of wheels and diamond belts from us for thermal spraying coatings. wheels sizes various from Dia.50mm to D915mm. the other company called Alloy Coating Supply also our customers.

Moresuperhard can give you more suggestions and solutions on grinding and polishing thermal spraying coatings.

Suggestion for the surface roughness you want to achieve:

| Grinding wheel | Surface roughness |

| Resin diamond wheel 1A1-D750-H304.8-T50-X10 grit 100/120 |

Ra0.8

|

| Resin diamond wheel 1A1-D350*H127*T50*X10 | |

| Resin diamond wheel 1A1-D450/455*H254*T20*X10 | |

| Resin diamond wheel 1A1-D450*H254*T25*X10, 220# | |

| Resin diamond wheel 1A1-D500*H254*T40*X10, 220# | |

| Resin CBN wheel 1A1-D450*H254*T25*X10, 220# | |

| Resin CBN wheel 1A1-D500*H254*T40*X10, 220# |

Q&A:

What’s the thickness of layer ?

Thickness of diamond layer T=75mm, width of diamond layer X=10mm.

What’s the concentration ?

100% concentration.

What kind of diamond are used?

Type 1.5, high quality.

How clean or dress the wheel?

Generally do not need to dress, if need you can use diamond oil stones.

How to dressing resin diamond grinding wheel?

About dressing of this D750 wheels, one best way is to use a grinding wheel, here I take a video for your reference.

But it has requirements for the machine.

If easy dressing, diamond dressing sticks can be ok.