Case of Electroplated Diamond Honing Reamer for Honing Valve Guide

This article will discuss the valve guide, why it needs honing, the honing process, and the specific advantages of using electroplated diamond honing reamers for honing valve guides.

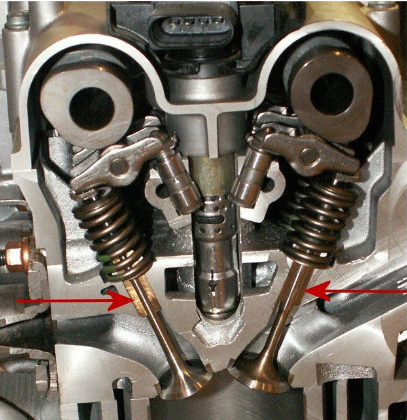

What is a Valve Guide?

Key Functions of a Valve Guide:

-

Alignment: Ensures proper alignment of the valve within the engine.

-

Lubrication: Holds a small film of oil to lubricate the valve stem, minimizing wear.

-

Heat Dissipation: Transports heat from the valve to the cylinder head.

-

Wear Resistance: Protects the valve stem from excessive wear.

Valve guides are often made from durable materials such as cast iron, bronze, or steel alloys. They come in various sizes, depending on the engine model and the specific requirements of the vehicle or machine.

Why Do Valve Guides Need Honing?

Honing is a precision machining process used to improve the surface finish and dimensional accuracy of internal cylindrical surfaces, such as valve guides. Over time, valve guides undergo wear due to constant friction between the valve stem and the guide itself. This wear can cause various issues, including:

-

Increased Friction: As the valve stem moves within the guide, friction increases due to wear. This causes reduced efficiency in valve movement and can lead to overheating.

-

Loss of Valve Seal: If the guide becomes worn or deformed, it can affect the seal between the valve and the guide, leading to reduced engine performance and increased emissions.

-

Inconsistent Valve Movement: Uneven wear or misalignment of the valve guide can cause the valve to move erratically, affecting the timing and overall function of the engine.

To ensure a smooth, efficient, and long-lasting valve operation, valve guides need to maintain an accurate bore size and a high-quality surface finish. Honing is an essential process to restore the required dimensions and surface finish, eliminating issues such as misalignment, excessive friction, and poor sealing.

Why Valve Guides Need Honing

Several reasons make honing essential for valve guides:

-

Achieving Precision: Valve guides must maintain very tight tolerances to ensure the valve stem moves smoothly. Honing helps to restore these tolerances and remove any imperfections that can arise due to wear or manufacturing.

-

Surface Finish: A smooth surface finish on the inside of the valve guide is necessary to reduce friction between the valve stem and the guide. Honing helps to achieve the optimal surface finish, which in turn improves performance and extends the life of the valve and guide.

-

Removal of Imperfections: Manufacturing processes like casting or drilling may leave slight imperfections inside the guide. Honing helps to eliminate these imperfections and ensure a consistent and smooth surface.

-

Improved Lubrication: The honing process helps to create the ideal surface texture for proper oil retention. This reduces friction and enhances the lubrication between the valve stem and the guide.

How to Hone Valve Guides

Honing valve guides involves a precise process to achieve the desired bore size, surface finish, and roundness. The honing process for valve guides typically involves the following steps:

-

Preparation:

-

Ensure that the valve guide is securely placed in the fixture or machine, ensuring the workpiece is stable.

-

Select the appropriate honing tool based on the material of the valve guide and the specifications for size and finish.

-

-

Tool Selection:

-

Choose the right honing tool, such as a diamond honing reamer or electroplated diamond reamer. The tool’s abrasive properties and geometry must match the material of the valve guide to provide the correct finishing.

-

-

Honing Process:

-

Apply a honing lubricant or coolant to reduce friction, prevent overheating, and enhance tool life.

-

The tool is rotated or moved in a precise manner, removing small amounts of material to achieve the desired bore size and finish.

-

Throughout the process, it is essential to ensure the honing tool is correctly aligned and calibrated to maintain the required accuracy.

-

-

Final Inspection:

-

After honing, inspect the valve guide for its dimensional accuracy, surface finish, and roundness.

-

Verify that the guide meets the specifications for fit and finish and that the required tolerance is achieved.

-

Advantages of Electroplated Diamond Honing Reamers for Honing Valve Guides

When it comes to honing valve guides, electroplated diamond honing reamers offer several key advantages over conventional honing tools. These advantages make electroplated diamond reamers an ideal choice for manufacturers seeking precision, efficiency, and reliability.

1. Superior Cutting Efficiency

Electroplated diamond honing reamers are designed with a high density of diamond abrasive particles on the cutting surface. The diamond abrasives are highly efficient in cutting through hard materials such as steel, cast iron, and other metals commonly used in valve guide construction. As a result, these tools can remove material more quickly and precisely than conventional honing tools, improving production speed and reducing machining time.

2. Longer Tool Life

Diamond is one of the hardest known materials, making it highly durable. Electroplated diamond honing reamers have a much longer tool life than traditional abrasives such as carbide or CBN. The electroplating process ensures that the diamond particles are firmly attached to the reamer, ensuring consistent performance and longevity.

3. High Precision and Surface Finish

The sharpness and hardness of the diamond abrasives result in a smoother and more precise finish on the valve guide bore. The honing process creates a high-quality surface with minimal roughness, which is critical for reducing friction between the valve stem and the guide. This results in better performance and longer service life for both the valve and the valve guide.

4. Reduced Tool Wear and Maintenance

Because of the wear resistance of diamond, electroplated diamond honing reamers suffer from minimal wear during use. This translates into fewer tool replacements and reduced maintenance, lowering operational costs for manufacturers.

5. Versatility

Electroplated diamond honing reamers can be used on a variety of materials commonly used in valve guides, including hard alloys, steel, and cast iron. This versatility makes them an excellent choice for manufacturers who work with multiple materials or need to hone valve guides for different engine types.

6. High Quality and Consistency

Since diamond abrasives maintain their sharpness for longer, they ensure a consistent cutting action throughout the honing process. This leads to improved consistency in valve guide dimensions and surface finishes, which are crucial for high-performance engines.

7. Cost-Effectiveness in the Long Run

Although electroplated diamond honing reamers might have a higher upfront cost compared to conventional honing tools, their longer tool life, higher efficiency, and minimal maintenance needs make them more cost-effective in the long term. They help reduce downtime, increase productivity, and lower overall machining costs.

Recently Moresuperhard have received on inquiry about honing valve guide,lets see it together:

| Honing stone type | Electroplated honing reamer |

| Workpiece | Valve guide |

| Workpiece size | D7.836mmxL55mm |

| Workpiece material | COLSIBRO (Colsibro® is a precipitation hardening copper nickel silicon that offers a remarkable blend of physical and mechanical attributes unrivalled by many other grades of copper alloy.) |

| Workpiece hardness | 75 – 78 HRA |

| Honing request size | 7.886mm |

| Finish requirements | 2μm |

Conclusion

Honing is an essential process for maintaining the precision and performance of valve guides, which are critical components in engine systems. By using electroplated diamond honing reamers, manufacturers can achieve superior surface finishes, extended tool life, and greater efficiency compared to traditional honing tools. With their precision, durability, and versatility, diamond honing reamers provide excellent value for engine component manufacturers, especially those focused on high-performance applications.

The electroplated diamond honing reamers used in honing valve guides offer significant advantages such as increased tool longevity, reduced maintenance, and improved quality of the valve guide’s surface. These features make them an indispensable tool for manufacturers aiming for precision in their machining operations.

For engine manufacturers and machine shops involved in high-performance engine production, investing in electroplated diamond honing reamers for valve guide honing is a strategic decision that enhances both product quality and manufacturing efficiency.