Why CBN grinding wheel superior to Diamond wheel in Grinding Nitinol (NiTi)

Why Grinding Titanium Alloy Is So Difficult?

Nickel-Titanium (NiTi), commonly known as Nitinol, is a staple in the medical device industry due to its superelasticity and shape memory properties. However, for manufacturing engineers, it presents a unique challenge: it is notoriously difficult to grind.

A common misconception in the industry is that: because Nitinol is hard, it requires the hardest abrasive—Diamond. This is a costly mistake.

At Moresuperhard, we often see manufacturers struggling with rapid wheel loading, workpiece burns, and unstable dimensions when using Diamond wheels.

Why Diamond Reacts with Titanium

To understand why diamond wheels fail on Nitinol, we must look at the chemistry occurring in the grinding zone, where temperatures often exceed 700°C (1292°F).

1. The Carbon-Titanium Reaction

Diamond is composed of pure Carbon (C). Titanium (Ti) is a highly reactive metal with a strong chemical affinity for carbon at elevated temperatures.

According to fundamental principles of Tribology and Material Science, when a diamond abrasive cuts into a titanium alloy:

* Carbon atoms from the diamond crystal diffuse into the titanium matrix.

* This reaction forms a hard, brittle layer of Titanium Carbide (TiC).

2. The Result: Wheel Loading (Glazing)

This chemical reaction causes the “gummy” titanium chips to adhere (weld) to the abrasive grains. This phenomenon is known as Chemical Wear or Diffusion Wear.

* Consequence: The wheel porosity becomes clogged instantly.

* Risk: With the pores blocked, coolant cannot reach the cutting zone. This leads to excessive heat, causing micro-cracks and compromising the biocompatibility of medical guidewires or stents.

The Superior Solution: Cubic Boron Nitride (CBN) Grinding Wheel is ideal for NiTi Alloy

If Diamond is chemically incompatible, what is the solution?

Cubic Boron Nitride (CBN) is the second hardest material known to man, but unlike diamond, it contains no carbon. It is composed of Boron and Nitrogen.

Why CBN wheel Works for Nitinol:

* Chemical Inertness: CBN remains chemically stable and inert when in contact with Nickel (Ni) and Titanium (Ti), even at temperatures up to 1000°C.

* Cool Cutting: Because the chips slide off the crystal rather than welding to it, CBN wheels maintain their sharpness longer.

* Surface Integrity: Moresuperhard CBN wheels deliver superior Ra (Surface Roughness) values without inducing thermal damage to the superelastic crystal structure of Nitinol.

Comparison: Diamond vs. CBN for NiTi Alloys

| Feature | Moresuperhard CBN Wheel | Standard Diamond Wheel |

| Chemical Composition | Boron Nitride (BN) | Carbon (C) |

| Reaction with Titanium | Inert (No Reaction) | High Affinity (Forms TiC) |

| Primary Wear Mode | Slow Mechanical Wear | Rapid Chemical/Diffusion Wear |

| Grinding Temperature | Low (Cool Cutting) | High (Friction Heat) |

| Wheel Life | Extended | Short (Frequent Dressing Needed) |

| Verdict | Recommended | Not Recommended |

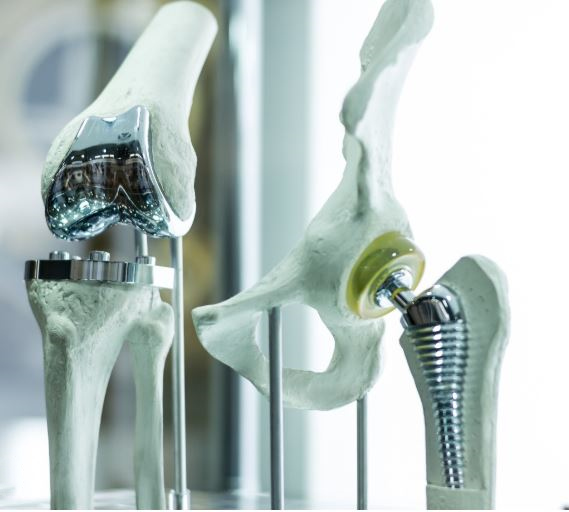

Typical CBN Grinding Wheel For Titanium Alloy Grinding Applications

CBN grinding wheels are commonly used for:

* Aerospace titanium structural components

* Medical titanium implants

* Titanium alloy bars and tubes

* Nickel-based superalloy components

* Precision shafts and high-strength parts

Depending on grinding type, different bonds of CBN wheel can be selected:

* Vitrified bond CBN grinding wheel(high precision, good self-sharpening)

* Resin bond CBN grindnig wheel (fine surface finish)

* Electroplated CBN grinding wheel(profile grinding)

At Moresuperhard, we develop customized CBN grinding wheels according to:

* Titanium material grade

* Grinding parameters

* Required surface roughness

* Machine type

Moresuperhard’s Approach: Customizing for the Medical Industry

Simply switching to generic CBN is not enough. The bonding system is equally critical. Moresuperhard specializes in custom-bonded CBN solutions tailored for:

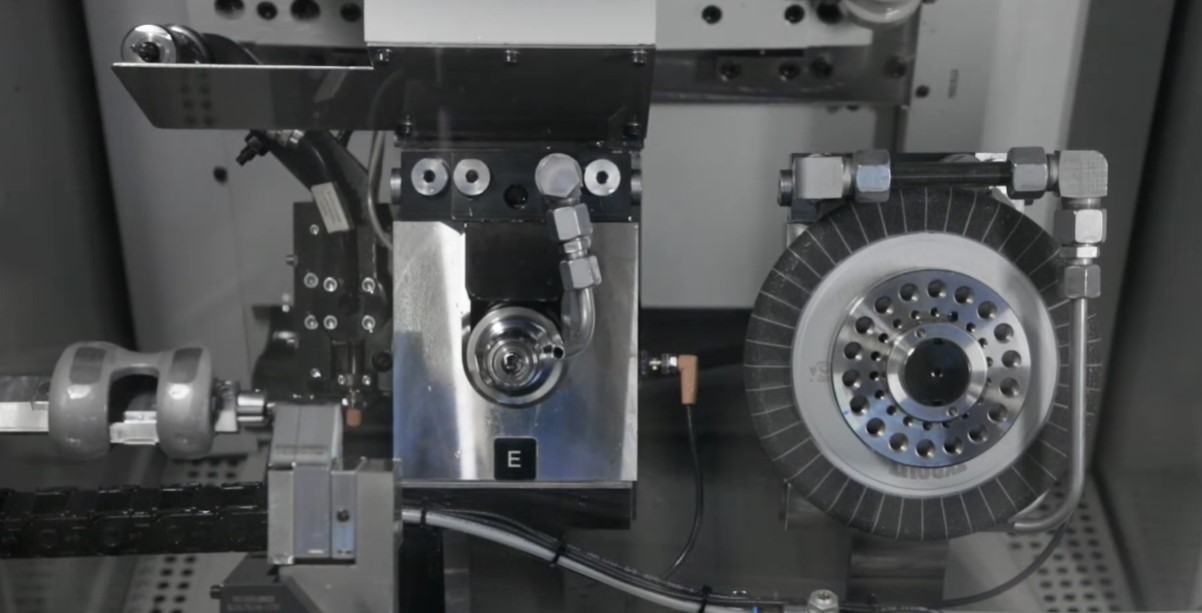

1. Medical Guidewires (Centerless Grinding)

* The Challenge: Maintaining tight diameter tolerances on long, thin wires.

* Our Solution: We utilize a high-porosity vitrified bond. This structure holds the CBN grain firmly while allowing maximum coolant flow to flush away long, stringy NiTi chips, preventing wheel loading entirely.

2. Nitinol Stents & Implants

* The Challenge: Achieving a mirror finish with zero micro-cracking.

* Our Solution:Resin-bonded CBN wheels with fine grit sizes (up to #2000 or finer) designed for precision finishing and polishing, ensuring the fatigue life of the implant.

Ready to Solve Your Wheel Loading Problems?

Stop compromising your workpiece integrity with the wrong abrasive. Switch to Moresuperhard’s chemically inert CBN solutions. Welcome to inquiry any about NiTi Alloy grinding solutions.