what material can be processed with vacum brazed diamond tools?

Vacuum Brazed Diamond Tools

MORE specializes in the production of diamond brazed tools that used in stone cutting and grinding.

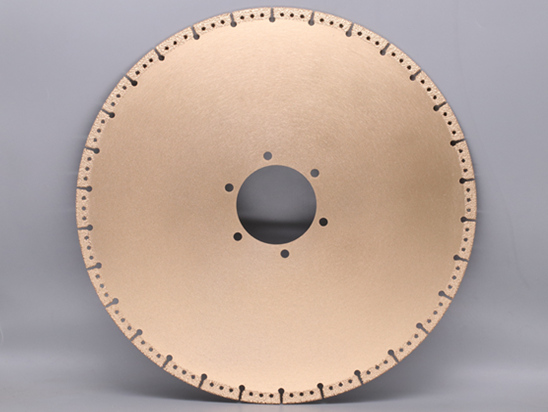

– Cutting: Diamond brazed saw blades, wire saws, and beads

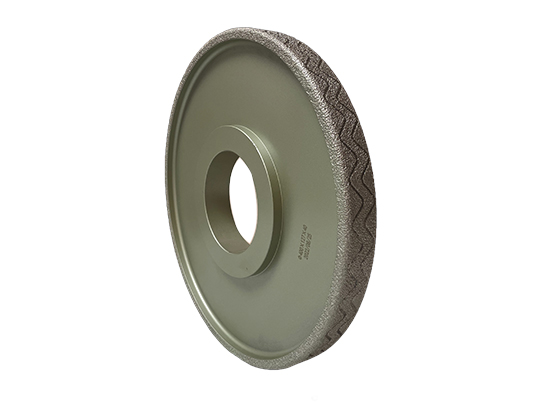

– Grinding: Brazed grinding discs, wheels, and portable wheels

– Drilling: Diamond brazed drill bits

Classification and Characteristics of Brazing

Brazing is divided into two categories based on the melting point of the filler metal:

1. Soft Brazing

– Brazing metal: Melting point below 450°C, such as tin-lead and cadmium-based alloys.

– Characteristics: Low joint strength (<70 MPa) and poor heat resistance, suitable for low-load applications such as electronic circuits and instrument components.

2. Hard Brazing

– Brazing metal: Melting point above 450°C, such as silver-based, copper-based, and nickel-based alloys.

– Characteristics: High joint strength (>200 MPa) and high-temperature resistance, suitable for high-strength components such as carbide cutting tools and bicycle frames.

What is the Vacuum Brazed Process?

Vacuum brazing is a high-temperature metal joining technique carried out in a vacuum furnace, where diamond particles are bonded to a tool’s metal body using a brazing alloy (commonly nickel- or cobalt-based).

1. Pretreatment: Clean the workpiece surfaces and assemble them into an overlapping joint.

2. Heating: Heat to above the melting point of the brazing filler metal. The liquid filler metal fills the gap through capillary action.

3. Diffusion Bonding: The brazing filler metal and the base metal diffuse into each other, forming a strong joint upon cooling.

Comparison with Conventional Grinding Wheels:

vs. Electroplated Diamond/CBN: Much stronger bond retention (3-4x), higher grit protrusion, better chip clearance, significantly longer life. Less prone to “shelling” (loss of entire electroplated layers). Higher initial cost but vastly superior cost-per-part.

vs. Resin Bond Diamond/CBN: Higher material removal rates (MRR), vastly superior dimensional stability, no need for dressing/conditioning, much longer life. Better heat dissipation. Less sensitive to coolant type. Generally higher initial cost.

vs. Conventional AlOx/SiC Wheels: Orders of magnitude longer life (especially on abrasive CI), much higher MRR potential, cooler grinding (reduced thermal damage risk), consistent performance without dressing. Significantly higher initial cost, but often lower cost-per-part on abrasive materials.

Applications of Brazed Diamond Grinding Wheels:

High-Efficiency Precision Grinding:

The high bond strength and wear resistance of brazed diamond grinding wheels make them particularly suitable for grinding processes requiring high material removal rates and stringent precision, such as grinding difficult-to-machine materials like carbide, ceramics, and glass.

Automotive Industry:

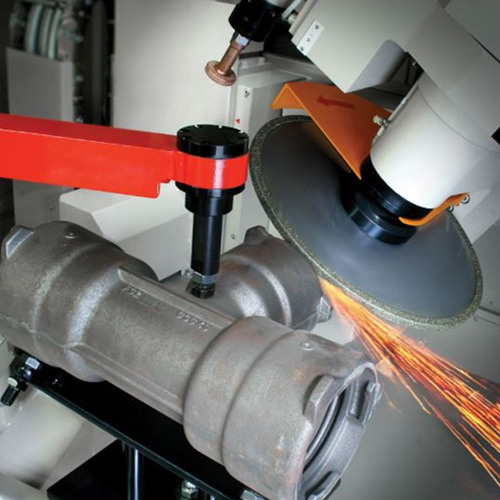

Brazed diamond grinding wheels are widely used in the grinding of automotive engine blocks, cylinder heads, crankshafts, and other components, meeting the automotive industry’s demand for high-precision, high-efficiency machining.

Aerospace Industry:

Brazed diamond grinding wheels play a vital role in the machining of key components such as aircraft engine blades and turbine disks, ensuring high performance and reliability.

Mold Manufacturing:

Brazed diamond grinding wheels can be used for grinding mold cavities, improving mold precision and lifespan, thereby enhancing mold production efficiency and product quality.

Other Industries:

In addition to the aforementioned industries, brazed diamond grinding wheels are also used in tool manufacturing, electronic component processing, and optical glass processing.

Why Vacuum Brazed Diamond Wheels Excel for Cast Iron

Overcoming Abrasiveness:

* Diamond Hardness: Diamond is the hardest known material (10 on Mohs scale), vastly superior to AlOx or SiC. It readily cuts through the hard carbide phases in cast iron without rapid dulling.

* Strong Bond Retention: The vacuum braze bond securely holds the diamonds despite the extreme abrasion, preventing premature pull-out – the primary wear mechanism becomes diamond micro-fracture and attrition, which is a slower, more controlled process.

* High Wear Resistance: The combination of diamond and the metallic bond matrix offers exceptional resistance to the abrasive wear of cast iron.

Minimizing Thermal Damage:

* High Protrusion & Chip Clearance: Efficient swarf removal prevents chips from being re-ground (“rubbing”), which is a major source of heat.

* Free-Cutting Action: Sharp diamonds and minimal rubbing reduce specific grinding energy (energy per unit volume removed), directly lowering heat generation.

* Efficient Heat Conduction: The steel core and metallic braze act as a heat sink, drawing heat away from the grinding zone faster than resin or vitrified bonds.

* Consistent Performance: No “glazing” or loading means heat generation remains stable throughout the wheel’s life.

* Coolant Effectiveness: Efficient chip evacuation allows coolant to penetrate the grinding zone effectively to cool the workpiece and flush chips.

Preventing Wheel Loading:

* Deep Chip Pockets: The large spaces between highly protruding grits provide ample room for swarf (iron particles, graphite) to escape.

* Reduced Rubbing: Sharp diamonds cut efficiently, minimizing the generation of fine, sticky swarf that causes loading in conventional wheels.

* Lack of Bond Matrix: Unlike vitrified or resin wheels, there is no porous bond structure for the soft iron/graphite to become mechanically embedded in. The smooth braze surface is difficult for material to adhere to.

Achieving High Material Removal Rates (MRR):

* Aggressive Cutting: Sharp, well-retained diamonds combined with high grit protrusion allow for deep cuts and fast feed rates.

* High Power Utilization: The rigid steel core transmits high spindle power efficiently into the cut without deflection or vibration.

* Continuous Operation: Long tool life and absence of dressing requirements mean the wheel spends maximal time actually removing material.

Ensuring Precision and Consistency:

* Minimal Wheel Wear: Diamond wear is very slow and predictable on cast iron. The rigid core ensures minimal deflection.

* No Dressing Required: Eliminates the variability and inaccuracy introduced by the dressing process on conventional wheels. The wheel geometry is fixed at manufacture.

* Stable Process: Consistent cutting forces and minimal thermal distortion lead to highly repeatable dimensions and surface finishes part after part.

—EDITOR: Doris Hu, Anna Wang

—POST: Doris Hu