The difference between grinding fluid and polishing fluid

Principle

Grinding fluid

The principle of the grinding fluid mainly relies on the mechanical grinding effect of the abrasive particles. Through a large grinding force, it removes the thicker material layer and larger defects on the semiconductor surface, achieving the initial flattening. Grinding fluid is generally used in the first coarse grinding and the second fine grinding process of the grinder.

Both water-based and oil-based grinding fluids are widely used in grinding equipment, and both provide cooling functions. So what are the differences between their properties?

Characteristics of Oil-Based Grinding Fluids

Grinding speed is fast and efficient, but oil-based fluids are difficult to clean. This is because oil is a lubricant, which increases the rotation speed of the grinding disc during grinding, which inadvertently increases grinding speed and productivity. Furthermore, oil-based fluids have a high degree of adhesion, making cleaning after grinding more laborious.

Characteristics of Water-Based Grinding Fluids

Easy to clean, but with a lower stock removal rate than oil-based fluids. Water, a common liquid without many properties, does not accelerate grinding speed during the grinding process. Therefore, this type of grinding fluid lags slightly behind oil-based fluids in terms of grinding efficiency. However, water-based fluids do have the advantage of being easy to clean.

Grinding fluids have a wide range of applications:

-In semiconductor manufacturing:

Grinding fluids are an essential component of chip fabrication, flattening the surfaces of silicon wafers and wafers, ensuring precision for subsequent processes such as multi-layer metal wiring and dielectric lithography.

-In optics:

Grinding fluids impart ultra-smooth surfaces to optical lenses and crystals, reducing light scattering and distortion for clearer images. Furthermore, in the processing of materials such as disk drive components, ceramics, and cemented carbide, grinding fluids enhance surface flatness and finish.

Polishing fluid

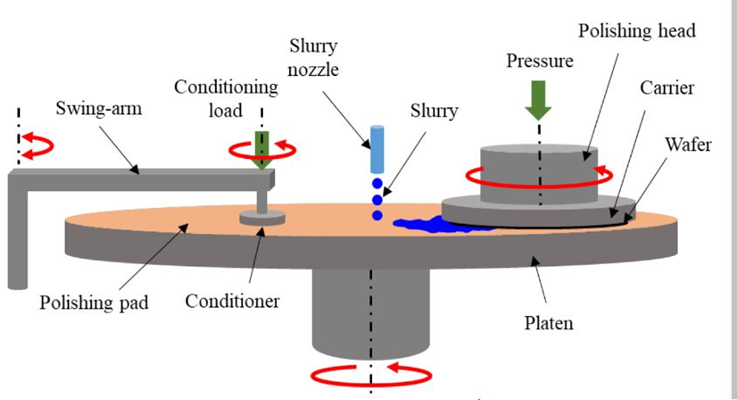

While the polishing fluid achieves this through the combined effect of chemistry and mechanics, the chemical action causes the surface material to undergo a chemical reaction to form compounds that are easy to remove. The mechanical action then uses tiny abrasive particles and a soft polishing pad to perform a minor grinding and removal on the surface, thereby obtaining a highly smooth, flat, and undamaged surface. Polishing fluid is only used in the second and third fine polishing processes.

There are many types of polishing slurries, most of which are customized according to the customer’s process. Based on the abrasive particles, they are roughly divided into silica polishing slurries, cerium oxide polishing slurries, aluminum oxide polishing slurries, and nano-diamond polishing slurries.

Based on the abrasive particles, polishing slurries are broadly classified into silica, cerium oxide, aluminum oxide, and nanodiamond polishing slurries.

Silicon dioxide polishing slurry: A high-purity, low-metal ion polishing product produced using a special process using high-purity silicon powder. It is widely used for nano-scale, high-planarization polishing of various materials.

Cerium oxide polishing slurry: Excellent stability and uniform particle size with an average particle size of 100 nanometers. It is used for polishing optical glass.

Aluminum oxide polishing slurry: Aluminum oxide polishing slurry is made from graded aluminum oxide powder, thoroughly mixed according to a special formula. It is used for rough, intermediate, and fine polishing of various workpieces.

Nanodiamond polishing slurry: Composed of high-quality diamond powder, a composite dispersant, and a dispersion medium, it offers a wide variety of formulations and is widely used for grinding and polishing hard materials.

Differences between grinding fluid and polishing fluid

Degree of action: The grinding fluid has a stronger grinding effect and removes a larger amount of material; the polishing fluid has a relatively milder effect and mainly performs fine surface refinement.

Surface effect: The surface after grinding is rougher and still has a certain degree of roughness; the surface after polishing can achieve extremely high flatness and smoothness.

Material removal amount: The grinding fluid removes a larger amount of material, while the polishing fluid removes less.

III. Technical Characteristics

Grinding Fluid

- High grinding efficiency: Can quickly remove a large amount of material.

- Particle size distribution control: Ensures that different particle sizes of abrasive materials work together to improve the grinding effect.

- Stability: Maintains stable performance during use.

Polishing Solution

* Precise chemical formula: Suitable for various semiconductor materials and process requirements.

* Low surface damage: Minimizes the impact on semiconductor performance to the greatest extent.

* High dispersion: Ensures uniform distribution of the abrasive material, achieving consistent polishing results.

Multiple Technologies

* Diamond Grinding Liquid: Extremely hard and with excellent grinding performance, suitable for grinding of third-generation semiconductor materials with high hardness.

* Silica Oxide Polishing Liquid: Chemically stable, commonly used in polishing processes with high surface precision requirements.

* Aluminum Oxide Polishing Liquid: Relatively low cost, performing well in some mid-to-low-end application scenarios.

Application Scenarios

Grinding Fluid

- Preliminary processing of semiconductor wafers to remove excess materials of a certain thickness.

- Rough grinding process during the manufacturing process, laying the foundation for subsequent polishing.

Polishing Solution

- Chip surface polishing in integrated circuit manufacturing to enhance electrical performance.

- Surface treatment of third-generation semiconductor power devices to improve reliability and stability.

- Surface trimming of optoelectronic devices to optimize optical performance.

Grinding fluid and polishing fluid each play unique roles in semiconductor manufacturing.

—EDITOR: Doris Hu,Anna Wang

–POST: Doris Hu