RELATED BLOG

-

Why CBN grinding wheel superior to Diamond wheel in Grinding Nitinol (NiTi)

2026-02-11 -

How to Choose the Right Grinding Wheel for Rubber Grinding

2026-01-29 -

How to Choose the Right Vacuum Brazed Diamond Tool

2025-12-17 -

How to Select the Right Polishing Pad Material for Different Sapphire CMP Stages

2025-12-07 -

Which Grit Wheel Should You Choose for Wood Turning Tools?

2025-12-04 -

Difference Between CVD Diamond Roller Dresser and Electroplated Diamond Roller Dresser

2025-11-18

-

What’s the application of CBN Wheels

2020-02-11CBN material is not only used for making cutting tools, but also for making CBN abrasive tools, which are used for high speed and high efficiency grinding and honing, which can greatly improve the grinding efficiency and the grinding accuracy and quality by one grade.Learn More

-

Will CVD diamond tools replace PCD tools?

2020-02-10CVD diamond tool can be made into two forms:One is to deposit a thin film with a thickness of less than 50um on the matrix, the mean is CVD diamond film layer tools. The other is to deposit the thick diamond film without substrate up to the thickness of 1mm, which is CVD diamond thick film welding tool. Diamond film layer tools are superior to PCD tools in some respects. It has a monolithic diamond surface coating and can be machined into cutting edges of any shape and geometry.Learn More

-

Should I use dry or wet milling?

2020-02-10Milling is essentially an interrupted process, this will causes the temperature at the cutting edge to fluctuate between high and low temperatures (approximately 1000 ° C).Learn More

-

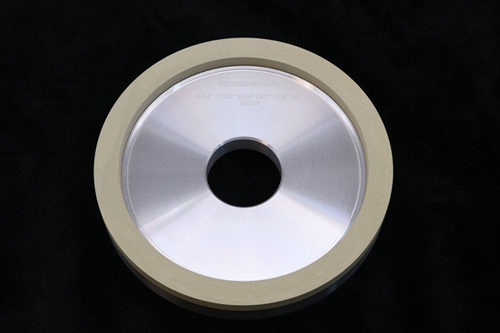

What’s the difference between Diamond and CBN Products

2020-02-07Resin Diamond Bond Wheels and Resin CBN Bond Wheels have been developed to meet the needs of precision grinding of hard materials. Natural and synthetic diamond and CBN abrasives manufactured with our high temperature bonds, guarantee high performing wheels that will grind hard materials. Wheel sizes for most CNC machines and wheels shapes for your grinding applications. If you do not find your required wheel we can manufacture to your specific needs.

Learn More

-

Double-Disc Grinding Technology

2020-02-05With Double-Disc grinding technology, parts are passed, one or more times, between two counter-rotating grinding wheels. Double-Disc grinding removes material from both sides of the part simultaneously, providing surfaces that are flat and parallel in just one operation. This technology can be used for effective yet efficient production of one-of-a-kind parts or millions of the same parts.

Learn More

-

Types of DIA and CBN

2019-12-11Abrasive is strong-retention,heat-resistant,superior wear resistance. Used for easily deformed job or job required higher grinding performance,especially in grinding and cutting for glasses,lens,iron oxides,ceramics. And the conditions are both dry grinding and wet grinding.

Learn More

-

CNC tool grinder diamond grinding wheel automatic dressing and compensation method

2019-12-11As a high efficiency grinding tool, diamond grinding wheel is widely used in the processing of hard alloy, ceramics, CBN and other superhard materials. The dressing and automatic compensation method of diamond grinding wheel determine the performance of automatic CNC grinding machine, which largely determines the performance and service life of the grinding wheel.

Learn More

-

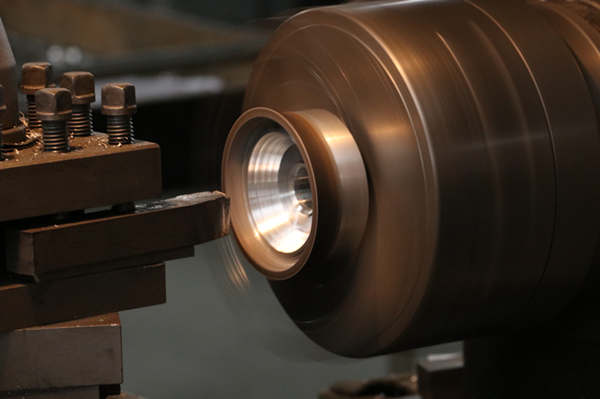

How to select the grinding wheel hardness of CNC cylindrical grinder

2019-12-11CNC cylindrical grinding machine is very common in die factory and hardware processing plant, and has become the common equipment of the majority of mechanical industry technicians, in the operation of the cylindrical grinding machine, the choice of abrasive is very important.The harder the grinding roller surface, the softer the grinding wheel hardness should be.Learn More

-

Types of DIA and CBN

2019-12-11Abrasive is strong-retention,heat-resistant,superior wear resistance. Used for easily deformed job or job required higher grinding performance,especially in grinding and cutting for glasses,lens,iron oxides,ceramics. And the conditions are both dry grinding and wet grinding.

Learn More

-

Grinding crack generation and solution

2019-12-05Surface grinding cracks (black chips) are not formed by sudden cracks, but appear sporadically on the surface of the workpiece.

Learn More