RELATED BLOG

-

Why CBN grinding wheel superior to Diamond wheel in Grinding Nitinol (NiTi)

2026-02-11 -

How to Choose the Right Grinding Wheel for Rubber Grinding

2026-01-29 -

How to Choose the Right Vacuum Brazed Diamond Tool

2025-12-17 -

How to Select the Right Polishing Pad Material for Different Sapphire CMP Stages

2025-12-07 -

Which Grit Wheel Should You Choose for Wood Turning Tools?

2025-12-04 -

Difference Between CVD Diamond Roller Dresser and Electroplated Diamond Roller Dresser

2025-11-18

-

Different from the past grinding -HVOF grinding technology

2020-09-03The HVOF coating materials in aviation parts has had a positive impact on the aerospace industry. HVOF coating materials are not only more environmentally friendly but also more resistant to wear and tear and therefore last longer. During the migration, there is also a shift in the grinding process used to produce the parts. While resin-bonded diamond wheels are an old standard, vitrified bonded diamond wheels are now more popular because resin-bonded diamond wheels cannot be dressed in machines. This poses a challenge to maintaining consistency. By using a vitrified bonded diamond grinding wheel, one can use a rotary dresser and a rotary dressing diamond wheel on the spindle to dress the grinding wheel. This breaks the situation that diamond grains can only be bonded in the grinding wheel, creating a completely new cutting surface on the grinding wheel. Bonding operations can be done online and during the manufacturing process

Learn More

-

Magnesia grinding wheel

2020-09-02Calcined at 800 ~ 850℃, calcined with natural magnesite as raw material, magnesia is a kind of fine powdery gas rigid cementation material. The color is pure white, or gray, or near pale yellow, fresh material has a shimmering glassy sheen. Specific gravity 3.2, bulk density 800 ~ 900 kg/m3, magnesia content not less than 75%, coagulation time: initial coagulation no earlier than 40 minutes, final coagulation no later than 7 hours.

Learn More

-

Grinding process VS Rolling processing

2020-09-01Grinding process and rolling process can improve the dimensional accuracy of parts and reduce the surface roughness.But there are the following differences.

Learn More

-

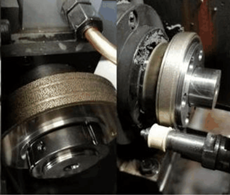

The History and Types of Gear

2020-08-31A gear is a kind of machine element in which teeth are cut around cylindrical or cone shaped surfaces with equal spacing. It is widely used in mechanical transmission and the whole field of machinery.

Learn More

-

Four methods of grinding wheel dressing

2020-08-28The process of shaping or trimming the blunt surface of the grinding wheel with a dressing tool to restore the grinding performance and correct geometry of the working surface. Timely and correct dressing of grinding wheel is an indispensable link to improve grinding efficiency and ensure grinding quality. Grinding wheel dressing generally includes turning, diamond roller, grinding and rolling, etc.

Learn More

-

Analysis of blockage factors of grinding wheel

2020-08-26The influence of grinding wheel linear velocity is more complex, because of the increase in wheel linear velocity grinding grain of the maximum cutting depth is reduced, chip cross-sectional area is reduced, cutting and grinding heat increases at the same time, the two factors can make jam quantity increases, but when the grinding wheel linear velocity up to a certain extent, such as more than 50 m/s) grinding wheel blocking quantity drops greatly.

Learn More

-

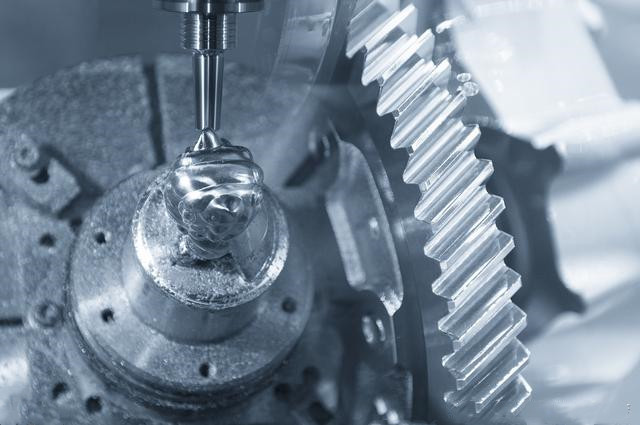

Control method of glass grinding edge chipping

2020-08-25The most common problem encountered when grinding glass is that the amount of edge chipping exceeds the range ,so why does edge chipping occur? The reason is that glass has an amorphous and irregular non-crystalline structure, which means that edge chipping is inevitable and random when grinding glass. The input determines the output effect in the grinding system. The four major input factors are equipment, tools, parameters, and workpieces. The edge chipping is the result of the combined effect of these factors.

Learn More

-

Honing is a three-in-one metalworking process

2020-08-24Honing is the ultra-precise machining process trusted by job shops and high-production manufacturers to create parts that perform at the highest levels of speed and efficiency. No boring or grinding process is capable of delivering such fine levels of roundness, straightness and surface detail. When integrated into your manufacturing process, honing is the difference between a part that works and a part that performs.

Learn More

-

Automobile box processing program-overall PCBN face milling insert and cutter

2020-08-21Learn More

-

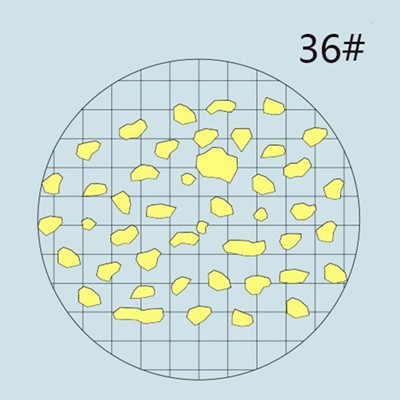

Diamond and CBN Abrasive Grain Size Control

2020-08-19Mesh refers to the number of holes on the screen per square inch, 50 mesh means 50 holes per square inch, 500 mesh is 500, the higher the mesh, the more the holes, and the smaller the abrasive particle size. The finer the granularity. The filter screen divides the abrasive grains into different sizes.

Learn More