How to machining carbon-ceramic brake disc?

Carbon-ceramic brake discs (commonly C/SiC or similar carbon-fiber-reinforced silicon-carbide composites) have become popular in high-performance and racing braking systems because of their very high specific strength, excellent high-temperature stability, and light weight. Those same material properties — extreme hardness, brittleness, and abrasive silicon-rich phases — make the parts difficult to machine and finish. For nearly all production and finishing operations on these materials you need superabrasive tools (diamond) and carefully chosen bonds (resin, vitrified, sometimes metal or electroplated) and process strategies to control wheel wear, surface integrity and cost.

Machining carbon-ceramic brake discs demands advanced superabrasive technology. The choice of diamond bond — resin, vitrified, or metal diamond grinding segment — determines the success of the operation.

Resin bond segments deliver fast, cool cutting for roughing.

Vitrified bond segments offer precision and fine surface finish for finishing.

Metal bond segments provide maximum durability and geometry stability for long runs or semi-finishing.

At Moresuperhard, we supply customized resin, vitrified, and metal bond diamond grinding segments engineered specifically for carbon-ceramic brake disc machining. Our engineers optimize:

-

Diamond grit size and concentration

-

Bond hardness and porosity

-

Segment geometry and mounting design

to ensure stable performance, superior surface finish, and high efficiency for every customer’s process.

Composition and Structure

Carbon-ceramic brake discs (often abbreviated as C/SiC) are carbon fiber reinforced silicon carbide composites. They are typically produced by infiltrating a porous carbon-fiber preform with molten silicon at high temperatures. During infiltration, the silicon reacts with the carbon matrix to form silicon carbide (SiC) while maintaining the carbon-fiber reinforcement.

The final composite consists of:

* Carbon fibers — provide toughness, strength, and thermal shock resistance.

* Silicon carbide matrix — provides hardness, stiffness, and wear resistance.

* Residual silicon or carbon — small fractions depending on processing method.

This hybrid structure delivers an outstanding balance of lightweight strength, high-temperature stability (up to 1,200 °C), and excellent friction properties, making it ideal for sports cars, aircraft brakes, and high-speed rail systems.

Machining Challenges

The very properties that make carbon-ceramic discs desirable — extreme hardness, brittleness, and inhomogeneity — also make them difficult to machine. Typical issues include:

* High hardness of SiC (≈ 9.5 Mohs) which quickly wears conventional abrasives.

* Composite microstructure that causes non-uniform cutting resistance and vibration.

* Brittleness leading to microcracks and chipping if not properly controlled.

* Thermal sensitivity — localized heat can cause delamination or residual stress.

Because of these challenges, diamond — the hardest known material — is the only suitable abrasive for efficient, stable grinding of carbon-ceramic composites.

What are “carbon-ceramic” brake discs and why they need diamond

Carbon-ceramic discs are composite components made by reinforcing a carbon-fiber preform with a ceramic matrix (often SiC) via high-temperature infiltration or chemical conversion (PIP, CVI, or silicon infiltration). The result is a composite with carbon fiber reinforcement in a silicon carbide (SiC) ceramic matrix (often abbreviated C/SiC). The matrix and any free SiC make the surface extremely abrasive and hard — harder than conventional steels or cast iron — so standard abrasives (alumina, silicon carbide) wear out quickly and cannot cut efficiently. Diamond is the practical abrasive of choice for grinding and finishing because it’s far harder than SiC and maintains cutting edges when machining these materials.

Key implications:

* Cutting is abrasive and causes high wheel wear if the wrong abrasive/bond is used.

* The material is brittle; improper grinding can produce subsurface cracks, delamination or thermal damage that degrades friction and lifetime.

Typical machining steps for carbon-ceramic brake discs

A production flow for a carbon-ceramic rotor often includes:

* Pre-shaping / green-state machining — before final infiltration, handling low-density, fragile preforms (special tooling).

* Post-infiltration roughing — remove bulk material / true up geometry (coarse diamond tools).

* Profiling and OD/ID turning — wheel or segment grinding to final contours and bore/face geometry.

* Finishing / superfinishing — final surface texture to meet friction/wear specs and to avoid asperities that induce noise or heat spots.

* Edge chamfering and balancing — small passes to remove burrs; dynamic balancing may be necessary.

Roughing uses more aggressive diamond tools and coarser grit; finishing uses finer grit, careful feed/overlap and lower depth-of-cut to preserve surface integrity. For tight geometrical tolerances, CNC grinding or form grinding with small-diameter diamond wheels or segments is common.

Grinding as the Key Process

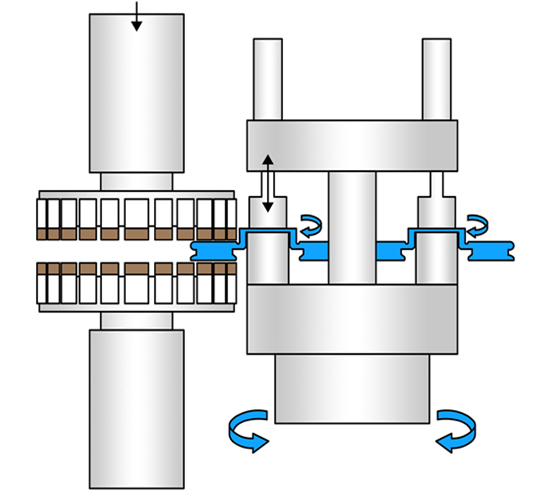

Among all operations, grinding is the most important step for final geometry and surface texture. Machining is typically carried out on CNC grinders equipped with segmented diamond wheels. The segments — bonded either with resin or vitrified materials — are mounted on a metal body or ring to form the working surface.

Key machining targets include:

* High material-removal rate (MRR) in roughing

* Low surface roughness (Ra ≤ 0.8 µm) for finishing

* Minimal subsurface damage

* Consistent dimensional accuracy and balance

Selecting the correct diamond bond and optimizing process parameters are crucial for achieving these goals.

Diamond Grinding Segments

A diamond grinding segment is composed of diamond grits held together by a bonding material. The bond determines how strongly the diamonds are retained and how fast the worn layer is renewed.

Resin Bond Diamond Segments

Characteristics

Resin bond diamond segments use an organic polymer as the matrix. They are:

* Elastic and shock-absorbing, reducing vibration and chipping.

* Self-sharpening, as the resin gradually wears to expose fresh diamond.

* Cool-cutting, since the soft bond generates less frictional heat.

These features make resin bonds ideal for high-removal roughing operations on carbon-ceramic materials, which are often brittle and non-uniform.

Advantages of resin diamond grinding segment

* Fast material removal — soft bond ensures continuous exposure of sharp cutting edges.

* Lower grinding temperature — reduced risk of thermal damage or delamination.

* Good surface integrity — less chance of micro-cracking.

* Adaptable to interrupted or variable cuts — resin’s elasticity tolerates uneven loads.

* Ease of dressing — segments can be dressed quickly for renewal.

Limitations

* Shorter lifespan — the soft bond wears faster than vitrified.

* Shape retention is lower — dimensional stability decreases over long cycles.

* Temperature limit (~ 200 °C) — bond softening at higher temperatures can accelerate wear.

Recommended Use

Resin bond diamond segments are best suited for:

* Rough grinding and stock removal

* Initial shaping of carbon-ceramic rotors after infiltration

* Operations with vibration or interrupted contact

* Machines with moderate rigidity

Typical parameters (indicative):

* Grit size: #46 – #120

* Wheel speed: 20 – 35 m/s

* Feed rate: 0.02 – 0.08 mm/pass

* Coolant: water-based emulsion or MQL

Vitrified Bond Diamond Segments

Characteristics

Vitrified bond segments are made from glassy or ceramic bonding materials fused at high temperature. This creates a hard, porous, and rigid structure with excellent shape retention.

Main features:

* High stiffness and dimensional stability

* Good thermal conductivity, allowing high-speed grinding

* Open porosity, improving coolant flow and chip evacuation

* Precise form holding, ideal for contour and finish grinding

Advantages

* Excellent form accuracy — ideal for precision finishing of brake disc surfaces.

* Long tool life — superior wear resistance reduces wheel changes.

* Higher thermal stability — can operate at higher speeds and loads.

* Stable surface roughness — consistent finish quality across batches.

* Customizable porosity — can be engineered for specific coolant or cutting conditions.

Limitations

* Brittleness — vitrified bond can fracture under heavy impact.

* Requires rigid machine setup — sensitive to vibration or misalignment.

* More difficult dressing — needs precise dressing tools and parameters.

5.4 Recommended Use

Vitrified bond diamond segments are suitable for:

* Fine finishing and final sizing

* High-precision surface and profile grinding

* Continuous grinding with stable contact

* Applications demanding tight tolerances and smooth finish

Typical parameters (indicative):

* Grit size: #120 – #400

* Wheel speed: 30 – 50 m/s

* Feed rate: 0.005 – 0.03 mm/pass

* Coolant: water-based emulsion or oil mist

Recommended Combination

For production grinding of carbon-ceramic discs, the hybrid process is the most efficient:

-

Stage 1 — Rough Grinding:

Use resin bond diamond segments with coarser grit to remove material quickly and generate basic geometry. -

Stage 2 — Precision Finishing:

Use vitrified bond diamond segments with finer grit to achieve final dimensions and a high-quality surface.

This combination minimizes total machining time while maintaining part quality and tool economy.

Choosing the Right Bond for Carbon Ceramic Brake Discs

Multi-Stage Strategy

The most efficient production method combines all three bond types across the machining stages:

Roughing:

Use resin bond segments (coarse grit) to remove bulk material quickly and safely. Their elasticity minimizes chipping and cracking in the brittle C/SiC matrix.

Semi-Finishing:

Switch to metal bond segments when shape retention and longer life are desired. They maintain consistent geometry over multiple parts, improving productivity.

Finishing:

Employ vitrified bond segments (fine grit) to achieve high precision, stable geometry, and excellent surface finish.

This three-stage combination balances cost, efficiency, and surface integrity.

—EDITOR:Doris Hu

—POST:Doris Hu