How to grind suspension springs?

Suspension springs are one of the most important components in modern automotive systems. They support the vehicle’s weight, absorb shocks from road irregularities, and maintain ride comfort and stability. To achieve these functions, suspension springs must have excellent dimensional accuracy, surface integrity, and fatigue resistance.

Among the several manufacturing steps — including coiling, heat treatment, shot peening, and coating — grinding is a critical finishing operation that directly influences spring performance and lifespan. The end faces of the suspension spring must be ground precisely flat and parallel to ensure uniform load distribution, proper seating, and consistent spring rate in service.

The final step in manufacturing automotive suspension springs is end double side grinding, ensure it can be installed properly in the vehicle suspension system as per the specifications.

MORESUPERHARD can provide a series of grinding wheels, including double-end face grinding wheels specially designed for rough grinding of spring blanks used in various types of internal combustion engines, diamond bowl-shaped grinding wheels for planing and chamfering of spring products, and diamond cone grinding heads for chamfering and deburring of spring cones.

What Are Suspension Springs?

Suspension springs are elastic mechanical components designed to store and release energy. They are typically made of high-strength spring steels such as SAE 9254, 65Mn, SUP9, or Cr–Si alloys. These steels have excellent elasticity, fatigue resistance, and the ability to withstand repeated cyclic loading.

Common types of suspension springs include:

-

Helical coil springs – used widely in passenger cars, trucks, and motorcycles.

-

Leaf springs – found in heavy-duty vehicles.

-

Air springs – used in modern luxury vehicles for adjustable ride height.

Among them, helical coil suspension springs are most common, and these are the ones that require precision end face grinding

Why Grinding Is Essential for Suspension Springs

After the coiling and heat treatment processes, the end faces of coil springs are uneven and rough. This unevenness can cause misalignment when the spring is mounted in the suspension system, leading to:

* Non-uniform load distribution

* Noise or vibration during compression

* Reduced fatigue life

To prevent these issues, the end faces of the springs are ground flat — a process known as spring end grinding.

Key Purposes of Grinding:

Precise length: Grinding can precisely control the length of the spring to meet the design requirements.

Improving flatness: Grinding can make the end face of the spring smooth, ensuring good contact between the spring and the connecting parts.

Suspension spring grinding is a necessary step in manufacturing high-quality suspension springs. It ensures that the size, flatness and performance of the spring meet the standards through precise processing, thereby guaranteeing the normal operation and driving safety of the car suspension.

Parts That Need to Be Ground

In a typical helical suspension spring, only the two end faces need to be ground.

Each end of the spring is generally closed and ground to provide stable seating. The key features include:

Ground end surface: Flat surface created after grinding for stable support.

Spring end coil: The last coil is usually bent to form a closed end, which is then ground.

Transition area: The region between the last active coil and the end coil, where stress concentration can occur.

Ensuring proper grinding at both ends is vital for the spring’s function, as these surfaces directly contact the suspension mount.

How Suspension Spring Grinding Is Done

Spring grinding is typically performed on specialized spring end grinding machines, which can be single-end or double-end types.

Single-End Grinding

In single-end grinding, only one end of the spring is ground at a time. The spring is loaded into the machine, rotated, and pressed against a grinding wheel. Once one side is finished, it is flipped to grind the other end.

This method is suited for small batch production and lower volume applications.

Double-End Grinding

In high-volume production, double-end spring grinders are used. Springs are placed between two horizontal grinding wheels — one rotating clockwise and the other counterclockwise. The springs are compressed and rotated between the wheels to grind both ends simultaneously.

This ensures:

-High productivity

-Parallel end faces

-Consistent dimensions

Challenges in Grinding Suspension Springs

Grinding suspension springs presents several challenges:

High Hardness of Material

Spring steel is typically hardened (HRC 45–55) after heat treatment, which makes grinding difficult. Abrasive wear is significant.

Spring Deformation

The flexible nature of the spring can cause vibration or uneven contact during grinding, affecting surface accuracy.

Heat Generation

Continuous grinding can cause excessive heat buildup, leading to surface burns or microstructural damage.

Wheel Loading and Wear

The ductile nature of spring steel can cause chips to adhere to the grinding wheel, reducing its efficiency.

How to Choose Grinding Wheel for Spring Grinding

Spring end grinding is a key process step that determines the flatness, parallelism, and surface quality of coil springs. The right grinding wheel is essential for ensuring productivity, precision, and long service life of both the wheel and the springs.

| Bond Type | Features | Typical Use in Spring Grinding |

| Vitrified Bond | Hard, rigid, excellent shape retention, easy dressing | High-precision, double-end grinding machines |

| Resin Bond | Softer, good self-sharpening, cool cutting | Fine finishing, single-end machines |

| Rubber Bond | Elastic, for fine surface polishing | Rarely used for heavy-duty spring grinding |

| Metal Bond | Extremely strong, for super finishing | Not common for steel springs |

]Conventional Abrasive wheel for spring

Composition

Aluminum Oxide (A or WA) or Silicon Carbide (C) grains

Vitrified bond to provide rigidity and porosity

Advantages

Lower initial cost

Easily dressable for re-profiling and reusing

Available in multiple grit sizes for rough or fine grinding

Stable performance for soft or medium-hard spring steels

Limitations

Shorter wheel life — wear rate is much higher

Frequent dressing required — causes downtime

Higher heat generation — risk of surface burns or residual stress

Inconsistent geometry over time due to wear

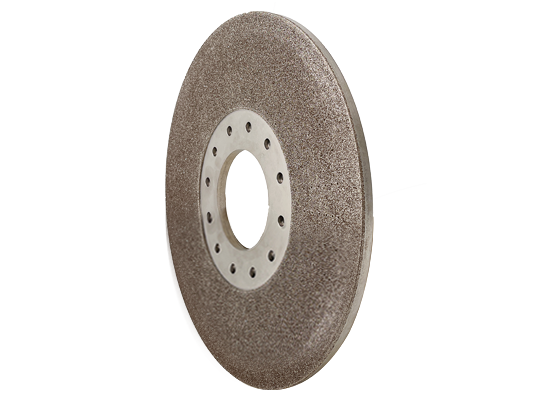

Inserted-Nut Grinding Wheels

Nut-inserted disc wheels are widely used in grinding of bearing rings and roller end faces, sealing valve plates, automobile friction plates, double end faces and four sides of engine cylinders, etc. Nut-inserted disc wheels have high grinding efficiency and high grinding precision.

Moresuperhard manufactures nut inserted disc wheels in sizes ranging from 305 mm – 1830 mm in diameter.

Electroplated CBN grinding disc for spring

CBN grinding wheel is used for compression springs surface grinding on double disc spring grinders. More Superhard used CBN disc can be stripped and re-electroplated with new grit, if the steel body is not damaged.

Applicable Spring Grinder

Moyer,OMD, Wafios, Dorn, Herckelbout, Hack, Bamatec, Kamatech and Bennet Mahler,etc.

—EDITOR:Doris Hu,Anna Wang

—POST: Doris Hu