How to Choose the Right Vacuum Brazed Diamond Tool

Why Vacuum Brazed Diamond Abrasives are the Ideal Choice for Hard and Brittle Materials

The core advantages of vacuum brazed diamond abrasives stem from their unique manufacturing process and structural design, which allows them to exhibit performance far superior to traditional abrasives in grinding hard and brittle materials.

(I) Vacuum Brazing Technology and Metallurgical Bonding Principle

Vacuum brazing is a process that uses heating in a vacuum environment to melt the brazing material, achieving a “metallurgical bond” between the diamond abrasive particles and the abrasive base.

Unlike traditional resin binders (which rely on resin adhesion) and electroplated binders (which rely on metal plating adhesion), the vacuum brazed bonding layer forms a strong chemical metallurgical bond with the diamond abrasive particles and the base. This bonding method not only significantly improves the holding force of the abrasive particles but also effectively prevents premature shedding of the abrasive particles during high-load grinding, fundamentally extending the service life of the abrasive tool.

(II) Core Advantages Compared to Electroplated and Resin-Bonded Abrasives

Higher Abrasive Particle Protrusion:

The vacuum brazing process allows the protrusion height of the diamond abrasive particles to reach 50%-70% of their own particle size (resin-bonded abrasives typically only reach 30%-40%, and electroplated abrasives are prone to reduced protrusion due to excessive plating thickness). Higher protrusion means a larger cutting space for the abrasive particles, allowing for rapid chip removal and reducing the problem of “clogging” caused by chip accumulation, especially suitable for materials that produce a large amount of chips, such as gray cast iron and ceramics.

Sharper and More Durable Cutting Edges:

Due to the strong bonding, the diamond abrasive particles maintain a stable cutting posture during grinding and are less prone to “wobbling” or “chipping.” Even when processing materials prone to work hardening, such as stainless steel, they can continuously maintain sharp cutting edges, avoiding problems such as sudden increases in grinding force and workpiece overheating caused by abrasive particle dulling.

Higher Heat Resistance and Load-Bearing Capacity:

The vacuum brazed joint layer has a high melting point (usually exceeding 800℃) and excellent thermal conductivity. In heavy grinding scenarios (such as rough grinding of gray cast iron blanks), it can effectively conduct grinding heat, preventing the grinding tool from softening and failing due to high temperatures. At the same time, the high strength of the joint layer can withstand greater grinding pressure, preventing deformation or fracture of the grinding tool.

Suitable for Typical Metal and Ceramic Processing Scenarios:

In actual production, vacuum brazed diamond grinding tools have become the “standard tool” for processing various hard and brittle materials, such as:

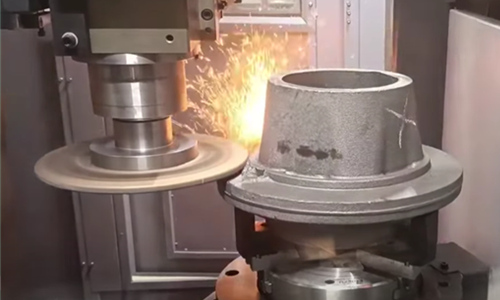

Gray cast iron: Rough and semi-finish grinding of engine cylinder blocks and machine tool beds, requiring rapid material removal and control of surface tearing;

Stainless steel: Precision grinding of medical device parts and food machinery components, requiring avoidance of work hardening and material adhesion;

Ceramics: Fine grinding and polishing of electronic ceramic substrates and ceramic bearings, requiring ensuring edge integrity and freedom from cracks.

Material Characteristics Directly Affecting Abrasive Tool Selection

The microstructure and physical properties of gray cast iron, stainless steel, and ceramics differ significantly. These characteristics directly determine the diamond grit size, structural design, and grinding parameters of the abrasive tool, and are the core basis for selection.

Gray Cast Iron: Highly Abrasive, Contains Graphite Structure, Prone to Surface Tearing

Gray cast iron contains a large amount of flake graphite distributed in its matrix. This structure gives it good damping properties, but also leads to “uneven hardness”—the graphite areas are softer, while the matrix areas are harder. At the same time, gray cast iron produces a large amount of hard abrasive debris (such as cementite) during grinding, which causes “secondary wear” on the abrasive tool, making it a typical “abrasive material.”

Furthermore, if the grinding parameters are inappropriate, “delamination” can easily occur at the interface between the graphite and the matrix, leading to surface tearing and affecting processing quality. Given these characteristics, when selecting an abrasive tool, it is necessary to focus on “wear resistance” and “chip removal capacity” to prevent premature wear of the abrasive tool or clogging by debris.

We advice choosing medium grain and high concentration for gray cast iron processing, then that can keep a balance between the grinding work effectiveness and avoide causing excessive damage to the workpiece surface.

For grinding gray cast iron materials, it is recommended to choose brazed diamond tools with a moderate grit size and high concentration. Such tools can ensure grinding efficiency while avoiding excessive damage to the gray cast iron surface.

Stainless Steel: Prone to Work Hardening, High Heat Generation, and Material Adhesion

Stainless steel (especially austenitic stainless steel, such as 304 and 316) has good plasticity and high toughness. During grinding, the compression of the cutting edge on the material causes plastic deformation of the surface metal, forming a “work-hardened layer” (hardness can increase by 30%-50%). This hardened layer, in turn, exacerbates abrasive wear, creating a vicious cycle of “getting harder the more it is ground.”

At the same time, stainless steel has a low thermal conductivity (only 1/3 of that of gray cast iron), and grinding heat easily accumulates on the workpiece surface, leading to overheating and deformation of the workpiece, and even “burning.” In addition, stainless steel chips at high temperatures are prone to adhering to the surface of the abrasive tool, forming an “adhesion layer,” clogging the gaps between the abrasive grains, and causing the abrasive tool to lose its cutting ability.

Therefore, abrasive tools for stainless steel need to consider both “sharpness” and “heat dissipation” to reduce work hardening and material adhesion.

It’s too hard processing because high hardness and toughness, then it’s important to use small grain size and higher bonding strength brazed tools.

Ceramics: Extremely high hardness, high brittleness, and prone to cracking

Ceramics (such as alumina ceramics and silicon nitride ceramics) typically have a hardness of HRA85 or higher, and some high-performance ceramics (such as zirconia ceramics) have a hardness close to that of diamond, belonging to the category of “superhard materials”; However, ceramics are also extremely brittle and have poor impact resistance. During grinding, if the local stress exceeds the fracture strength of the material, microscopic cracks (or even macroscopic chipping) are easily generated. In addition, ceramics have extremely poor thermal conductivity, and the grinding heat is concentrated in the cutting area, which easily leads to “thermal shock,” further increasing the risk of cracking.

For ceramic processing, the core of abrasive tool selection is “controlling grinding stress” and “protecting edge integrity,” and it is necessary to avoid cracks caused by excessively coarse abrasive grains or excessive grinding force.

Brazed diamond tools with uniform grit and high sharpness should be selected. Proper parameter selection can effectively prevent cracking and chipping of ceramic materials during grinding.

Matching Logic of Material Characteristics with Abrasive Tools and Parameters

The behavior of the material directly determines the selection of key parameters of the abrasive tool:

Materials with strong abrasive properties (such as gray cast iron) → require the selection of high-hardness, high-wear-resistant diamond abrasive grains, and the abrasive tool structure needs to be open (to facilitate chip removal);

Materials that are prone to work hardening (such as stainless steel) → require the selection of highly sharp abrasive grains (such as single-crystal diamond), and the abrasive tool needs to have a good heat dissipation design (such as cooling grooves);

Brittle materials (such as ceramics) → require the selection of fine-grained abrasive grains to reduce the cutting force of a single abrasive grain, while controlling the grinding speed and feed rate to reduce stress concentration.

Selection Recommendation

| Metail | Selection Influence | Recommended Model |

| Gray iron | It has relatively low hardness, but contains graphite and other components, so tools need to have a certain degree of self-sharpening properties. | 125mm |

| Stainless steel | It has high hardness and high viscosity, requiring tools with good wear resistance and anti-adhesion properties. | 150mm |

|

Ceramic

|

Due to its high hardness and brittleness, tools with appropriate particle size are required to ensure processing quality. | 100mm |

Selecting the Appropriate Diamond Grit Size and Quality for Different Materials

Diamond grit size (abrasive particle size) and quality (crystal type) directly affect grinding efficiency, surface roughness, and tool life. These parameters must be precisely matched to the material characteristics and processing requirements.

Gray Cast Iron: Coarse Grit for Rough Grinding, Balancing Efficiency and Surface Quality

The main processing requirement for gray cast iron is “rapid material removal” (e.g., rough grinding of blanks). Therefore, coarse-grit diamonds (e.g., 80#-120#) are recommended for the rough grinding stage. Coarse-grit abrasives have larger cutting edge spacing and wider chip evacuation channels, allowing for rapid removal of the large amount of chips produced by gray cast iron, preventing clogging. At the same time, coarse-grit tools offer high grinding efficiency, shortening the processing cycle.

For the semi-finishing stage (where surface roughness needs to be controlled, such as Ra1.6-Ra3.2), it is recommended to switch to medium-grit abrasives (e.g., 150#-200#) to ensure a certain level of efficiency while reducing the risk of surface tearing.

Stainless Steel: Medium to Fine Grit for Optimized Surface Control and Avoiding Work Hardening

Grinding stainless steel requires balancing “efficiency” and “surface quality,” avoiding excessive work hardening caused by overly coarse abrasives. For conventional stainless steel parts (such as medical device components), medium-grit abrasives (e.g., 120#-180#) are recommended. This ensures a certain grinding efficiency while reducing the pressure exerted by individual abrasive particles on the material, thus reducing the thickness of the hardened layer. If higher surface quality is required (e.g., Ra0.8 or below), fine-grit abrasives (e.g., 200#-320#) should be selected to achieve fine grinding through dense, fine cutting edges, reducing surface scratches.

It is particularly important to note that overly coarse abrasives (e.g., below 60#) should not be used for grinding stainless steel, as this can easily lead to excessive grinding force, exacerbating work hardening and material adhesion.

Ceramics: Fine and Ultra-Fine Grit Sizes Ensure Edge Integrity

The brittleness of ceramics necessitates a “low-stress grinding” strategy; therefore, fine or ultra-fine diamond abrasives are recommended. For precision grinding (such as ceramic substrate processing), 200#-400# grit sizes are commonly used. By employing small cutting forces and multiple cutting edges, localized stress concentrations are reduced, preventing cracks.

If polishing is required (such as for ceramic bearing surfaces), ultra-fine grit sizes (such as 600#-1000#), or even micro-powder abrasives, are needed to achieve a mirror-like surface (Ra0.02-Ra0.1).

Furthermore, ceramic grinding should avoid excessively fine abrasives that lead to low efficiency – this can be balanced with quality through “multi-stage grinding” (rough grinding → fine grinding → polishing).

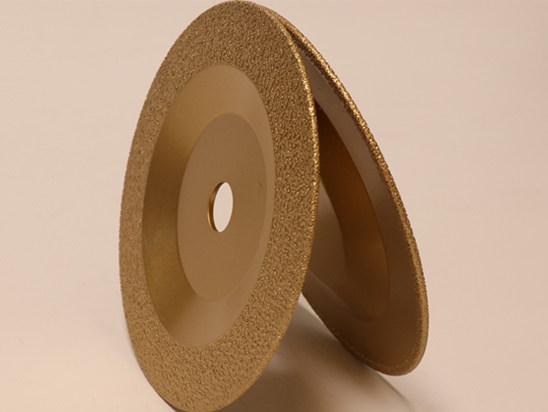

The Relationship Between Diameter, Hole and Thickness:

The diameter specifications (180mm/150mm/125mm/100mm) of brazed diamond grinding tools are closely related to the hole diameter and edge thickness. Generally speaking, the larger the diameter, the larger the hole diameter and edge thickness will be. Larger diameter tools are suitable for grinding large-area flat surfaces, while smaller diameter tools are more suitable for fine curved surface grinding.

Abrasive Tool Geometry and Design Considerations for Ensuring Stable Grinding Performance

The geometry (such as grinding wheels, cup wheels) and structural design (such as chip removal grooves, base strength) of abrasive tools directly affect grinding stability, chip removal efficiency, and heat dissipation. These factors must be considered in conjunction with the specific machining application.

(I) Selection of Abrasive Tool Type: Application Scenarios for Grinding Wheels, Cup Wheels, and Grinding Heads

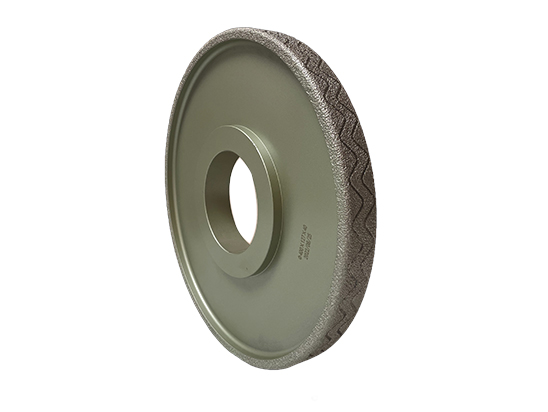

Grinding Wheels (Parallel Grinding Wheels, Beveled Grinding Wheels):

Suitable for large-area surface grinding (e.g., gray cast iron machine tool beds, stainless steel plates). They have a large contact area and high grinding efficiency; beveled grinding wheels can also be used for stepped surfaces or angle grinding.

Cup Wheels (Straight Cup Wheels, Bowl-shaped Cup Wheels):

Suitable for end face grinding and edge finishing (e.g., ceramic bearing inner rings, stainless steel flange end faces). Their “cup-shaped” structure prevents interference between the side of the abrasive tool and the workpiece, making them suitable for complex contour machining.

Grinding Heads (Cylindrical Grinding Heads, Spherical Grinding Heads):

Suitable for grinding in confined spaces such as inner holes and grooves (e.g., inner holes of stainless steel pipes, ceramic mold cavities).

They are small in size and highly flexible, allowing them to reach complex structural areas.

(II) Segment Layout and Open Structure: Enhancing Chip Removal Capability

The grinding segment is the core area of the abrasive tool where diamond abrasive particles are embedded. Its layout and structure are crucial for chip removal:

Gray Cast Iron Grinding:

A “sparse tooth layout” of the grinding segments (large spacing between segments) is recommended, combined with an “open structure” (chip removal grooves within the segments) to quickly remove a large amount of chips and prevent clogging;

Stainless Steel Grinding:

The grinding segment layout can be slightly denser (to ensure cutting continuity), but “spiral chip removal grooves” should be provided on the segment surface to promptly remove adhering stainless steel chips;

Ceramic Grinding:

The grinding segment layout needs to be uniform to avoid localized concentration of abrasive particles leading to stress concentration. The structure should be “semi-open,” balancing chip removal and heat dissipation.

(III) Substrate Strength and Vibration Control: Ensuring Machining Stability

The strength of the grinding tool substrate (the metal or composite material part supporting the grinding segments) directly affects grinding stability:

Heavy-duty grinding (e.g., rough grinding of gray cast iron):

High-strength metal substrates (such as 45# steel, aluminum alloy) should be selected to prevent substrate deformation and avoid grinding tool “wobbling”;

High-speed grinding (e.g., precision grinding of stainless steel, speed > 3000 r/min): The substrate needs to undergo “dynamic balancing treatment” (balance grade G2.5 or higher) to reduce vibration and prevent ripples on the workpiece surface;

Ceramic precision grinding: Lightweight materials (such as titanium alloy) can be selected for the substrate to reduce the inertia of the grinding tool, facilitating precise control of grinding depth and protecting the edges.

Cooling Groove and Airflow Design: Adapting to Dry Grinding Scenarios

Some processing scenarios (such as stainless steel medical devices, to avoid coolant contamination) require dry grinding, in which case the cooling design of the grinding tool is particularly important:

Cooling grooves: Annular cooling grooves are opened on the grinding tool substrate or grinding segments, utilizing the airflow generated by high-speed rotation to carry away grinding heat and reduce workpiece temperature;

Airflow channels: Through airflow channels are designed between the grinding segments to accelerate air circulation and prevent heat accumulation.

Dimensional Accuracy and Balancing Requirements: Meeting Precision Grinding Needs

For precision parts made of ceramics and stainless steel (such as electronic ceramic substrates, stainless steel sensor housings), the dimensional accuracy and balance grade of the grinding tool need to be strictly controlled:

Dimensional accuracy: The outer diameter tolerance of the grinding tool needs to be controlled within ±0.05mm to ensure uniform grinding depth;

Balance grade: High-speed grinding (speed > 5000 r/min) requires a balance grade of G1.0 to avoid dimensional errors caused by vibration;

End face runout: The end face runout of the grinding tool needs to be <0.02mm to prevent “height differences” during end face grinding.

Optimizing Bonding Strength, Thermal Control, and Processing Parameters

The performance of vacuum-brazed grinding tools depends not only on their design but also on optimizing bonding strength, thermal control, and processing parameters to avoid common failures (such as abrasive grain

detachment and workpiece burning).

(I) Vacuum Brazing Bonding Strength: Enhancing Diamond Retention

Bonding strength is a core indicator of vacuum-brazed grinding tools. High-quality grinding tools require the following bonding strength:

Tensile strength: ≥50MPa (to ensure abrasive grains do not detach under high load);

Heat resistance:

Maintaining stable bonding below 800℃ (to prevent softening at high temperatures during regrinding).

When selecting, pay attention to the manufacturer’s “brazing process certification” (such as ISO 13395 standard), or judge through “grinding tests”: if a large number of abrasive grains detach during normal grinding

(manifested as diamond particles mixed in the grinding debris), the bonding strength is insufficient.

(II) The Heat Generation Problem in Stainless Steel Grinding: Key Measures for Temperature Control

The low thermal conductivity of stainless steel easily leads to high grinding temperatures, requiring control from both the grinding tool and parameters:

Grinding tool selection: Prioritize grinding tools with cooling grooves, or use a “porous matrix” (such as a porous ceramic matrix) to improve heat dissipation;

Parameter optimization:

Reduce the grinding depth (single pass depth ≤0.05mm) to reduce the heat generated per unit time; increase the feed rate (within the limits of acceptable surface quality) to shorten the contact time between the workpiece and

the grinding tool.

—EDITOR: Doris Hu, Anna Wang

—POST: Doris Hu