How to Choose the Right Grinding Wheel for Rubber Grinding

Rubber and metal differ fundamentally in their physical properties. Rubber’s low hardness, high elasticity, and poor thermal conductivity present unique challenges during grinding, including clogging, heat buildup, and deformation. Selecting the appropriate grinding wheel is crucial for ensuring processing efficiency, surface quality, and wheel life, directly determining the final performance and production benefits of rubber parts.

Rubber Material Properties and Core Grinding Challenges

The mechanical properties of rubber differ significantly from those of metals, and different types of rubber exhibit varying processing difficulties. These characteristics collectively determine the complexity of the grinding process.

Common Rubber Materials and Core Mechanical Properties

The rubber materials commonly used in industrial grinding are mainly divided into two categories: natural rubber and synthetic rubber. The characteristics of each material directly affect the selection of grinding processes:

Natural Rubber (NR): Excellent elasticity, low hardness (Shore A 30-60), easily deformed and adhered during grinding;

Nitrile Rubber (NBR): Strong oil resistance, medium hardness (Shore A 40-80), better wear resistance than natural rubber, but debris easily adheres during grinding;

Ethylene Propylene Diene Monomer (EPDM): Good weather resistance and aging resistance, excellent elasticity, but prone to thermal deformation during grinding;

Silicone Rubber: High temperature resistance, strong corrosion resistance, relatively low hardness (Shore A 20-50), easily softened during grinding;

Polyurethane (PU): Wide hardness range (Shore A 50-95), combines elasticity and wear resistance, but high-hardness PU is more difficult to grind.

The common mechanical properties of various types of rubber are: low hardness (Shore A 20-95, far lower than metals), high elasticity (easily deformed under stress, returning to its original shape after unloading), and poor thermal conductivity (thermal conductivity only 1/100-1/50 of metals). These properties are the core source of the challenges in grinding.

Typical Rubber Grinding Applications

Rubber grinding applications focus on the molding, finishing, and precision assurance of parts, mainly including four categories:

Deburring and finishing of molded rubber parts (e.g., edge treatment of sealing rings and rubber gaskets);

Surface grinding of rubber sheets and rollers (e.g., surface leveling and roughness control of printing rollers and conveyor rollers);

Centerless grinding of rubber rollers (e.g., outer diameter precision machining of industrial rubber rollers to ensure roundness and dimensional consistency);

Precision dimensional finishing (e.g., thickness control and end face finishing of high-precision rubber seals).

Four Core Challenges of Rubber Grinding

The properties of rubber present significantly greater challenges to rubber grinding than metal grinding. These core challenges are concentrated in four areas:

Wheel Clogging and Adhesion:

Rubber debris is soft and highly adhesive, easily adhering to the surface and pores of the grinding wheel during grinding, leading to wheel clogging and a sharp drop in cutting ability.

Heat Accumulation and Rubber Coating:

Rubber has poor thermal conductivity, preventing the rapid dissipation of heat generated during grinding. This can cause the rubber to soften or even melt, coating the grinding wheel and workpiece surfaces and compromising machining accuracy.

Elastic Deformation Affects Machining Results:

Rubber is easily bent and deformed under stress, unlike metal which is directly cut. This results in fluctuations in grinding force, easily causing defects such as tearing and burrs, making it difficult to achieve a clean cutting surface.

Instant Dimensional Accuracy:

The combined effects of elastic and thermal deformation make it difficult to maintain tight tolerances on rubber workpieces, making it challenging to control dimensional and positional tolerances such as roundness and flatness.

Scientific Selection Method for Rubber Grinding Wheels

The selection of grinding wheels suitable for rubber grinding should be based on five core dimensions: abrasive type, grit size, bond type, wheel hardness, and structural characteristics. Simultaneously, process parameters should be optimized to avoid common selection pitfalls.

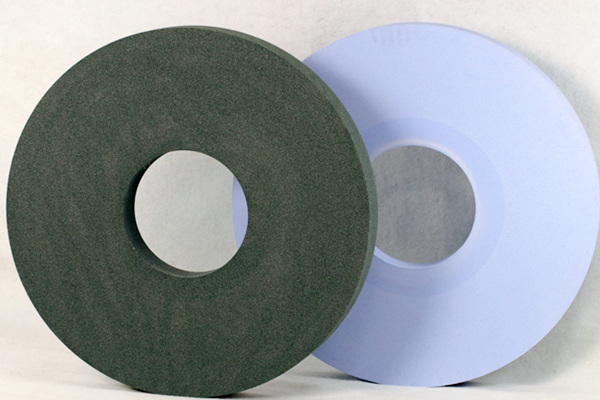

Abrasive Type: Silicon Carbide (SiC) is the Preferred Choice

The abrasive is the core of the grinding wheel’s cutting performance. The core requirements for abrasives in rubber grinding are “sharpness and good self-sharpening properties.” The compatibility of different abrasives varies significantly:

Silicon Carbide (SiC): The preferred abrasive for rubber grinding.

Its cutting edge is sharp, its hardness is higher than that of impurities inside the rubber, and it possesses excellent self-sharpening properties—after the abrasive grains wear down, they automatically break off, exposing new sharp cutting edges. This effectively prevents wheel dulling and clogging, while reducing the compression deformation of the rubber, ensuring clean cutting;

Aluminum Oxide (Al₂O₃): Limited compatibility.

Alumina abrasive grains are tough but lack self-sharpening properties. When grinding rubber, they are easily encased by the soft rubber, quickly losing their cutting ability. They are only suitable for light grinding of high-hardness polyurethane (Shore A 90+).

Diamond and cubic boron nitride (CBN): Generally incompatible.

These superhard abrasives have extremely high hardness, but their cutting edges are too sharp, easily causing rubber tearing. Rubber debris easily adheres to the abrasive grain surface, making it impossible to achieve a stable grinding effect. They are mostly used for hard and brittle materials, not elastic rubber.

Grit Size: Matching Processing Needs and Rubber Hardness

Grit size determines the cutting efficiency of the grinding wheel and the surface roughness of the workpiece. It needs to be precisely selected according to the processing stage (rough grinding/fine grinding), rubber hardness, and surface quality requirements:

Coarse grit (16-36 mesh):

Suitable for large-scale removal and flash removal scenarios. Large abrasive grain size, wide cutting edge spacing, and ample chip removal space allow for rapid removal of rubber flash and excess material, resulting in high efficiency. However, it produces a relatively poor surface roughness (Ra 1.6-3.2μm), making it suitable for roughing in the initial stages of grinding.

Medium grit (46-80 mesh):

A general-purpose grit size suitable for most rubber grinding applications. Balancing cutting efficiency and surface quality, it can be used for surface leveling and general precision machining of rubber sheets and rollers, achieving a surface roughness of Ra 0.8-1.6μm. Suitable for common materials such as natural rubber and NBR.

Fine grit (100 mesh and above):

Suitable for precision finishing applications. Small abrasive grain size and dense cutting edges achieve a smooth surface finish (Ra 0.2-0.8μm), making it suitable for the final dressing of high-precision rubber seals and silicone rubber workpieces. However, it requires a soft binder and an open structure to prevent clogging.

Selection principles: The lower the rubber hardness (Shore A < 50), the more suitable medium to coarse grit is; the higher the hardness (Shore A > 80), the finer grit can be appropriately selected to balance cutting efficiency and surface quality.

Bond and Grinding Wheel Structure: Soft binder + open structure is key

The binder determines the fixation strength of the abrasive grains and the self-sharpening property of the grinding wheel. The grinding wheel structure affects chip removal and heat dissipation, both of which directly relate to the stability of rubber grinding:

Binder type: Soft binders are preferred.

Excessive abrasive grain fixation must be avoided in rubber grinding—soft binders allow worn abrasive grains to detach promptly, ensuring continuous self-sharpening of the grinding wheel while reducing compression on the rubber. Recommended bonding agents are resin-bonded agents (good toughness, excellent self-sharpening properties, suitable for most rubber grinding, and moderate temperature resistance) and rubber-bonded agents (good elasticity, which can buffer grinding impact, reduce rubber deformation, and is suitable for precision machining).

Hard bonding agents (such as ceramic bonding agents) should be avoided, as their excessive bonding strength prevents abrasive grains from detaching in time, easily leading to wheel dulling, clogging, and rubber coating.

Grinding wheel structure: Open structure is preferred.

Open structure grinding wheels have wide abrasive grain spacing and large pores, providing ample chip removal space for rapid removal of rubber debris and preventing clogging. At the same time, large pores facilitate heat dissipation, reducing rubber softening and melting caused by grinding heat. Furthermore, the grinding wheel porosity should be considered—higher porosity (generally ≥40%) results in better heat dissipation and chip removal, making it more suitable for grinding low-hardness, high-elasticity rubbers.

Grinding Wheel Hardness (Grade): Adapting to Rubber’s Elastic Properties

Grinding wheel hardness refers to the strength of the bond that holds the abrasive grains in place. The core principle of rubber grinding is “soft grinding wheels for elastic materials”:

Soft-grade grinding wheels (e.g., Chinese standard R-Z grade): Preferred for rubber grinding.

Soft grinding wheels have low bond strength, allowing abrasive grains to easily detach, effectively preventing wheel dulling and surface glazing. They also reduce grinding force, lowering the risk of rubber elastic deformation and tearing.

Hard-grade grinding wheels: Completely incompatible. Hard grinding wheels have firmly fixed abrasive grains that cannot be replaced promptly after wear. They are easily encapsulated by rubber debris, leading to wheel clogging, rubber surface smearing, and high grinding force, which exacerbates rubber deformation and thermal damage.

Matching Rules: The lower the rubber hardness (Shore A), the softer the grinding wheel grade should be. For example, soft silicone rubber (Shore A 20-40) is suitable for Z-grade soft grinding wheels, medium-hardness NBR (Shore A 50-70) is suitable for Y-Z-grade grinding wheels, and high-hardness PU (Shore A 80-95) is suitable for X-Y-grade grinding wheels.

Optimization of Process Parameters and Auxiliary Solutions

Scientific process parameters and auxiliary measures can maximize grinding wheel performance and avoid rubber grinding defects:

Grinding wheel speed: Recommended speed is 1500-3000 r/min (linear velocity 20-40 m/s).

Excessive speed can easily exacerbate heat accumulation and rubber softening, while insufficient speed increases cutting force, leading to rubber deformation and tearing.

Feed rate and depth of cut: Adopt the principle of “small feed, shallow grinding”.

Feed rate controlled at 0.05-0.2 mm/r, grinding depth not exceeding 0.1 mm per pass, to reduce grinding force and heat accumulation, and avoid rubber deformation;

Wet grinding vs. dry grinding: Wet grinding is preferred.

Wet grinding allows for rapid heat dissipation through coolant, while simultaneously flushing away rubber debris, reducing wheel clogging and rubber coating. Anti-adhesion agents (such as specialized grinding fluid additives) must be added to the coolant; Dry grinding is only suitable for small, light grinding operations and requires a high-pressure dust extraction device to promptly remove debris;

Dressing method: Regularly dress the grinding wheel using a diamond dressing pen (dressing depth 0.01-0.02 mm) to maintain the wheel’s surface sharpness and open structure, avoiding workpiece damage caused by forced grinding after clogging.

Common Selection Misconceptions and Avoidance Methods

In actual production, many selection misconceptions can lead to low grinding efficiency, workpiece scrap, and shortened grinding wheel life, which must be avoided:

Misconception 1: Using metal grinding wheels.

Using alumina ceramic-bonded grinding wheels, typically used for metal grinding, in rubber processing will lead to severe clogging, rubber tearing, and surface coating; this must be strictly avoided.

Misconception 2: Choosing excessively hard or fine grinding wheels.

Overly hard grinding wheels are prone to dulling and clogging, while overly fine grinding wheels (120 grit+) are difficult to remove chips and easily stick to the rubber without an open structure. Hardness and grit size must be matched according to processing requirements.

Misconception 3: Ignoring the importance of the bond and structure.

Focusing only on abrasive and grit size, and selecting grinding wheels with hard bonds and dense structures, even with silicon carbide abrasives, will not achieve stable grinding. Soft bonds and open structures must be prioritized.

Misconception 4: Grinding wheel speed too high.

Blindly increasing the speed in pursuit of efficiency will exacerbate heat buildup and rubber softening, leading to deterioration of surface quality. The speed must be strictly controlled within the recommended range.