Common grinding defects of centerless grinding machines and the methods

Parts out of round

1. There are annular threads on the surface of the parts

2. The coolant is not clean and there are chips or sand particles in it

3. At the exit, due to the heavy grinding, it is scraped by the edge of the grinding wheel

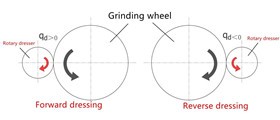

4. The center of the part is lower than the center of the grinding wheel, so that the sand and chips stick to the bracket

5. Grinding wheel dull

6. Too much margin under one grinding or too coarse grinding wheel, A very fine thread is formed on the other surface

Solution

1. Adjust front and rear guides

2. Replace coolant

3. Round the edge of the grinding wheel so that the 20mm at the exit of the part will not be used for grinding

4. Advance the center height of the parts properly

5. Dressing the grinding wheel

6. Properly reduce the amount of grinding and slow down the rate of modification

Cut off a small piece at the front of the part

1. The front guide plate protrudes from the surface of the guide wheel

2. The front end faces of grinding wheel and regulating wheel are not in a straight line and are quite different from each other

3. It’s worn at the entrance

Solution

1. Move the front guide back a bit

2. Replace or modify the longest of both

3. Reduce the amount of grinding at the entrance

The middle or end of the part is cut off

1. The rear guide plate lags behind the guide wheel surface

2. The center of the part moves too high, causing the part to jump at the exit

Solution

1. Move the rear guide slightly forward

2. Reduce the center height of the parts appropriately

Surface of the parts is not bright enough

1. Too large inclination of regulating wheel makes the cutting amount of parts too fast

2. The grinding wheel is modified too fast, and the grinding wheel surface is not bright

3. The regulating wheel is too rough

Solution

1. Reduce the inclination

2. Reduce the modification speed and modify the grinding wheel from scratch

3. Rebuilding regulating wheel

Note: Do not open the coolant before the grinding wheel is started. If it is necessary to open the coolant first, in order to prevent the occurrence of faults, intermittent switches should be adopted to wait until the coolant has been emitted from the surrounding area before starting to work.

More Superhard can provide excellent centerless grinding wheel to you, you can avoid a lot of grinding problems, save time, safe and assured.