Will CVD diamond tools replace PCD tools?

Will CVD diamond tools replace PCD tools?

At present, there are two kinds of diamond tools, single crystal diamond tools and polycrystalline diamond tools.

How to make single crystal diamond tool?

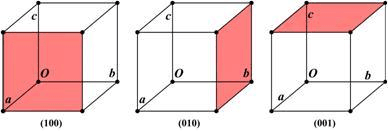

Crystal anisotropy:

The hardness, wear resistance, micro strength, easiness of grinding, and the friction coefficient with the work piece material in different crystal planes and crystal directions vary greatly. Therefore, when designing and manufacturing single crystal diamond tools The crystal direction must be selected correctly, and the crystal orientation of the diamond material must be performed. The choice of the rake face and flank face of the diamond tool is an important issue in the design of single crystal diamond tools.

Advantages of CVD diamond tools and PCD tools–

CVD diamond tool can be made into two forms:

One is to deposit a thin film with a thickness of less than 50um on the matrix, the mean is CVD diamond film layer tools. The other is to deposit the thick diamond film without substrate up to the thickness of 1mm, which is CVD diamond thick film welding tool. Diamond film layer tools are superior to PCD tools in some respects. It has a monolithic diamond surface coating and can be machined into cutting edges of any shape and geometry.

Hardness:

PCD is a mixture of diamond powder and binder sintered together, so the hardness is affected by the binder, while CVD diamond thick film is composed of pure diamond, its hardness is close to natural diamond, much higher than PCD hardness.

Bond:

The biggest difference between CVD diamond and PCD is that there is no binding agent, it is pure diamond, and it is made at low temperature (<1000deg.) and low pressure (< 0.1mpa), with low impurity content and nearly 100% purity.

Processing accuracy:

PCD cutting edge radius generally up to 0.1-0.5um.

Natural single crystal diamond tools can be in the range of 0.002-0.005um.

Therefore, natural diamond tools can be used for ultra-thin cutting and ultra-precision processing.

Tool performance and life:

Compared with PCD, CVD diamond has higher hardness, better wear resistance, smaller friction coefficient, higher thermal conductivity, and better chemical and thermal stability.

CVD diamond tool performance is better than PCD tool, tool life can be extended 2-3 times.

But the disadvantage of CVD diamond is not as tough as PCD and does not conduct electricity.