What Is Peel Grinding?

Two enabling technologies — superabrasive wheels and high precision servo control — come together to provide a contour grinding process that resembles an OD turning operation. For many medium volume OD grinding applications, this method may be a means to consolidate several manufacturing steps into a single setup.

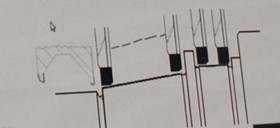

Production OD grinding traditionally is composed of process-specific steps. For complex workpieces in a medium-sized batch, these steps are often sequential. The work moves from one process-specific machine to the next. For example, a plunge or step grinding machine will finish bearing races and shoulders, a form grinding machine will clean up tapers and profiles, a thread grinding machine will cut fastening threads, and so on.

Individually, each process step is performed very quickly. An analysis of the total throughput time, however, reveals that significant savings could be made if work handling between operations could be reduced or eliminated. Additionally, keeping a workpiece on a single machine provides better workpiece accuracy because dimensional relationships between workpiece features can be maintained.

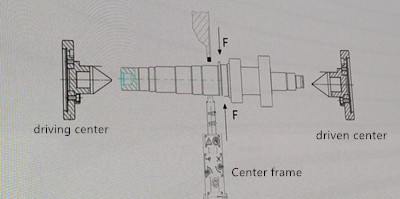

Peel grinding is a process that enables one machine to perform several grinding operations without removing the workpiece from the machine. Junker Machinery (Springfield, Massachusetts) uses this process on a line of machines it calls Quickpoint.

In peel grinding, a narrow (4 to 6 mm) grinding wheel is used. The wheel is dressed flat across its face. Using the two parallel pencils again as an example, swivel the pencil representing the grinding wheel half a degree. Now the contact area between the two is a single point. Basically, that model represents the wheel/workpiece contact in single point grinding. The grinding wheel’s angle of attack presents an edge of the wheel that makes the contact between the wheel and workpiece tangential.