The main points of the sharpening process of PCD and PCBN tools

One of the purposes of cutting tool sharpening is to obtain cost-effective cutting edge quality, and the key to quality is the choice of the size of the sharpening wheel. The finer the particle size of the grinding wheel, the smaller the chipping of the cutting edge, and the lower the grinding efficiency.

(1) The accuracy of the spindle should be good.

Generally, the end face of the grinding wheel should be ≤0.02mm. The end face of the grinding wheel jumps too much, and the grinding wheel intermittently impacts the cutting edge during grinding, which easily causes chipping of the cutting edge, and it is difficult to obtain a high-precision cutting edge.

(2) The grinding wheel should have a good dynamic balance.

The imbalance of the grinding wheel will cause the vibration of the machine tool, which will affect the cutting edge quality and machining accuracy of the processed tool.

(3) For sharpening grinding wheels, vitrified bond diamond grinding wheels should be preferred.

Because the ceramic bond is prone to microcracks during the grinding process, the abrasive grains are renewed and self-sharpened, so that the grinding process is stable, which is beneficial to improve the accuracy and efficiency of the processed surface. Secondly, the resin bond with higher heat resistance can be selected. Diamond grinding wheel.

(4) Pay attention to the sharpening of the grinding wheel at the right time, and the size of the sharpening whetstone should be appropriate. When processing PCD tools with diamond grinding wheels, the grinding wheels will be blocked, passivated, high temperature and rapid wear, resulting in reduced processing speed and vibration marks, noise, and burns. Usually choose the soft silicon carbide stone with a particle size of 1 to 2 that is finer than the grinding wheel used as the sharpening stone.

(5) Because diamond is easy to chemically diffuse with iron-based alloys and accelerate the wear of the grinding wheel, it should be avoided as much as possible to grind metal and PCD at the same time.

(6) The rotation direction of the grinding wheel must be rotated from the front face of the tool to the flank face.

From the force on the cutting edge of the PCD tool during grinding, it can be seen that when the grinding wheel rotates from the rake face of the tool to the flank face, the grinding force (the sum of tangential and normal forces) acts on the cutting edge inward, that is, the tool is subjected to Compressive stress is not easy to collapse; on the contrary, it is tensile stress, and the cutting edge is easy to collapse. If it is necessary to reverse the sharpening due to the tool structure, the resin bond grinding wheel is better than the metal and ceramic bond grinding wheel.

(7) In order to ensure the quality of the cutting edge and improve the grinding efficiency, the clearance angle of the tool can be divided into a large relief angle and a small relief angle. Use a coarse-grained grinding wheel to first grind the large relief angle, because the contact surface is large and the grinding force is large, and the grinding efficiency is high; then use a fine-grained grinding wheel to sharpen the small relief angle, and control the width of the small relief angle to about 0.1~0.3mm , The contact surface is small sharpened and the quality is good.

(8) As far as possible, complete the machining of the cutting edge of the tool in one clamping.

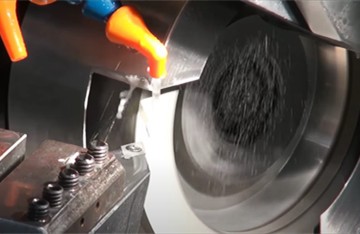

(9) PCD sharpening coolant should preferably be water-based grinding fluid.

Because PCD material has high hardness and poor heat resistance, the cooling effect of water-based grinding fluid is better than that of oil-based grinding fluid, which can improve processing efficiency and cutting edge quality. In addition, the cooling should be sufficient during the grinding process, and the flow should not be interrupted to avoid the large consumption (oxidation, graphitization) of the diamond (grinding wheel, tool) and the cutting edge damage of the tool due to the small amount of grinding fluid or the intermittent supply.

—EDITOR: Cindy Chen

—POST: Doris Hu