Super Hard Abrasive–Diamond

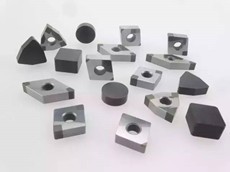

MORESUPERHARD is a professional manufacturer that processes the world’s hardest material-diamond into tools. Products (mainly used for drilling, grinding, polishing, cutting, etc.) are used in many fields such as automobiles, electronics, semiconductors, conveying machinery, machinery, bearings, knives, molds, glass, ceramics, civil engineering, mining, stone, construction, etc. Is widely used. We produce comprehensive professional tools for most diamond and CBN (boron nitride) products, such as grinding wheels, dressers, blades, band saw blades,drills, etc.

Diamond is the hardest material on the earth today. Alumina has the longest history in the grinding industry. Its good dressability can greatly increase its life and productivity by one hundred times that of alumina abrasives.

|

Characteristic: |

application | Mainly for grinding high hardness and non-ferrous materials (such as: cemented carbide, ceramics, etc.) |

| hardness | KNOOP HARDNESS 7000 | |

| Thermal sensitivity | 600°C | |

| Reactivity | Ferrous metals | |

| Be applicable: | Grinding polycrystalline blades and cemented carbide, etc.

Grinding of ceramic crystals, non-ferrous materials, etc. |

|

| TOUGHNESS | TYPE | GRAINRANEN | FEATURE |

| high | MDZ | 60~400 | Highest strength, suitable for poor equipment (metal connecting abrasive tools) |

| MDY

MDP

|

60~12000

60~1000 |

Neutral stroke, suitable for grinding ceramics, glass, etc. (MDP is used in electric grinding tools) | |

| low | MD

MDC BZC |

60~12000

60~3000 60~2200 |

High resistance, suitable for grinding cemented carbide, etc. (MDC is plated) |

Sand mesh

In addition to the standard, according to the American standard, the grit size ranges from 60 to 325, and the fine powder grade ranges from 400 to 14000. Please refer to the following table.

| number | 60 | 80 | 100 | 120 | 140 | 170 | 200 | 230 | 270 | 375 |

| Sand mesh | 60/80 | 80/100 | 100/120 | 120/140 | 140/170 | 170/200 | 200/230 | 230/270 | 270/325 | 325/400 |

| Average (μm) | 250 | 177 | 149 | 125 | 105 | 88 | 74 | 63 | 50 | 44 |

Micronized powder level:

| number | 400 | 500 | 600 | 800 | 1000 | 1200 | 1400 | 2200 | 3000 | 5000 | 8000 | 12000 | 14000 |

| Average (μm) | 40-60 | 38-54 | 22-36 | 20-30 | 15-25 | 10-20 | 10-15 | 5-10 | 4-8 | 3-6 | 2-4 | 1-3 | 0-2 |