Rotary diamond dresser for dressing grinding wheel

In the grinding process, due to the high temperature and mechanical load caused by the friction between the grinding wheel and the workpiece, the grinding wheel gradually loses its cutting ability and vibrates and burns, which greatly affects the surface integrity of the machined workpiece. In order to restore good sharpness and correct shape precision of grinding wheel, it is necessary to dress the grinding wheel regularly. The principle of diamond dressing roller is that the roller repairs the grinding wheel, and the grinding wheel repairs the workpiece. The grinding grain of the roller is harder than that of the grinding wheel, and the grinding wheel can be restored to its initial state.

At present there are diamond grinding wheel dressing methods mainly the single point diamond dresser and rotary diamond dresser. Single point diamond dresser, took the form of turning to dressing of grinding wheel, is reciprocating cutting feed mode, the modification method, simple and convenient operation, but for modalities such as bearing ring, blade plate of the root of the tenon, worm gear, tap and screw, etc. The raceway of bearing ring has multiple grooves of curvature, and it is difficult for diamond pen to dressing the grinding wheel of workpiece with complex surface. In this case, Moresuperhard diamond roller is needed. Moresuperhard diamond roller dressing can more effectively ensure the surface quality of processed workpiece.

Rotary diamond dresser dressing grinding wheel is different from single point diamond dresser. Moresuperhard diamond roller is in contact with the working face of the whole grinding wheel width in the dressing process. The cut dressing method can be formed in one time, with short dressing time and high efficiency.

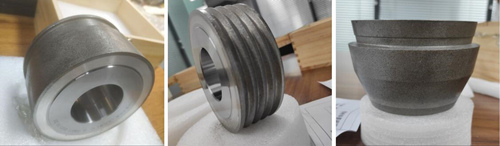

The structure of rotary diamond dresser: matrix, inner hole, working layer. The working layer mainly refers to the diamond layer, by electroplating or sintering process, or CVD strip inserts. The Moresuperhard rotary diamond dresser provides high precision, experienced inner hole, outer circular surface profile, and concentricity.

Grinding wheel dressing currently has four forms, which are electroplated diamond roller, sintered diamond roller, CVD diamond roller, electroplated roller CVD top strengthening (that is, the combination of CVD and electroplating or sintering process is strengthened). Electroplated diamond wheel can make modalities, such as amount of cutting, saw blade, blade of aeronautics and astronautics, gear, tap, valve in the fields of application is more, the sintering diamond roller is using artificial implant will be a large diamond particles according to a certain density of set in the graphite mould, the ball cage, bearings, guide rail sliding block, mostly in the screw in the fields of application. CVD diamond roller is more used for dressing CBN grinding wheel or diamond grinding wheel, also known as diamond disc or CVD dressing disc.

—EDITOR: Doris Hu

—EDITOR: Doris Hu