Control method of glass grinding edge chipping

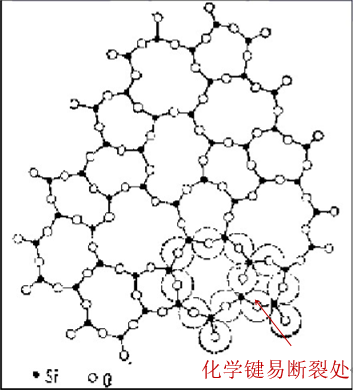

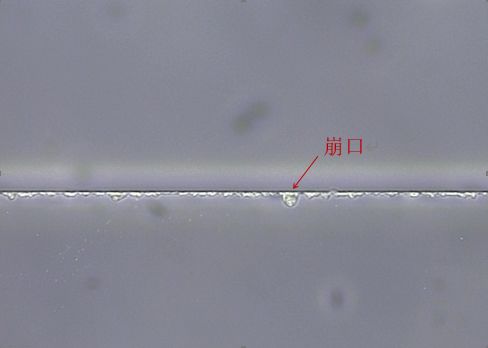

The most common problem encountered when grinding glass is that the amount of edge chipping exceeds the range ,so why does edge chipping occur? The reason is that glass has an amorphous and irregular non-crystalline structure, which means that edge chipping is inevitable and random when grinding glass. The input determines the output effect in the grinding system. The four major input factors are equipment, tools, parameters, and workpieces. The edge chipping is the result of the combined effect of these factors.

The characteristics that affect the grinding effect are: diameter, grit, groove angle, runout (concentricity).

1. Diameter

The smaller the diameter of the grinding wheel with the lower the grinding linear velocity, which will lead to the increase of grinding amount of single abrasive on the sand surface, thus increasing the grinding force and making it easy to produce edge breakage.

Therefore, the diameter of the grinding head should be a reasonable design of the diameter of the grinding head.

2. Grit

The coarser the grit size means the less abrasive particles on the surface, which also leads to the increase of grinding amount of abrasive during grinding, thus increasing the grinding force and making it more likely to produce edge breakage.

In order to effectively control the edge breakage in the required range, the diamond grit size should be selected reasonably.

3. Groove Angle

The Angle of the finishing groove will affect the amount of edge breakage to a certain extent, because the grinding wheel will produce compressive stress and shear stress in grinding the glass, and the shear stress is the biggest effect on the edge breakage. Reducing the Angle of the groove can make the force shift to the compressive stress so as to reduce the edge breakage.

However, it should be noted that the reduction of slot Angle will affect chip discharge to a certain extent, so it is very important to control the appropriate Angle.

4. Concentricity

Concentricity is also the beating size we often say, the bigger the beating, the more unstable the grinding head, the number of abrasive involved in grinding decreases, resulting in a single abrasive grinding volume, large force, resulting in the collapse of the more easy to produce.

Therefore, strictly control the concentricity of the grinding head is also the top priority.