Characteristics and application of precision grinding and ultra-precision grinding

The grinding accuracy that can be achieved by grinding has different precision ranges in different periods of production development. At present, According to the grinding accuracy, grinding can be divided into ordinary grinding (machining accuracy > 1μm, surface roughness Ra0.16 ~1.25μm), precision grinding (machining accuracy 1~0.5μm, surface roughness Ra0.04 ~1.25μm), ultra-precision grinding (machining accuracy ≤0.01μm, surface roughness Ra ≤0.01μm).

Precision machining refers to a certain period of development, processing accuracy and surface quality to a higher degree of processing technology, the current refers to the machining parts of the processing accuracy of L ~ 0.1µm, surface roughness value Ra0.2 ~ 0.01µm processing technology.

At present, precision grinding is one of the main methods for precision machining of ferrous metals such as iron and steel and brittle hard materials such as semiconductor, which plays a very important role in modern machinery and electronic equipment manufacturing technology.

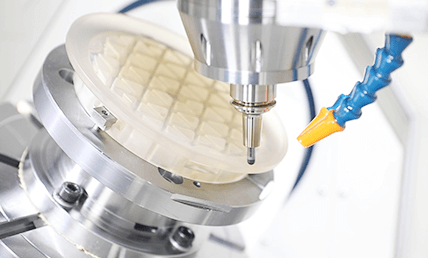

Precision grinding generally uses high hardness abrasive wheels such as diamond and cubic boron nitride, mainly by fine dressing of grinding wheel, using diamond dressing tools to small and uniform micro feed (10 ~ 15mm /min). Obtain a large number of contour micro edge, machining surface grinding trace is fine, and finally adopt no spark light grinding.

Precision grinding refers to the selection of fine grain grinding wheel on the precision grinding machine, and through the fine dressing of grinding wheel, so that the grinding grain has micro edge and isometric property. After grinding, the grinding marks left by the grinding surface are extremely fine and the residual height is extremely small.

Ultra-precision grinding refers to the processing accuracy of 0.1μm or less, surface roughness is less than 0.025 μm method, is a sub-micron level processing method, and is developing toward the nanometer level, suitable for the processing of steel materials, ceramics, glass and other materials. In recent years, the development of ultra-precision grinding is very fast, and there are some grinding processes related to ultra-precision grinding, such as mirror grinding, micro-grinding and high-speed grinding.

1. The characteristics of precision and ultra-precision grinding:

(1) Precision and ultra-precision grinding is a system engineering

Precision and ultra-precision grinding is not a simple machining method, it has formed a system engineering, its components are: machined materials, precision and ultra-precision grinding mechanism, precision and ultra-precision grinding machine, grinding wheel and dressing, workpiece positioning and clamping, detection and error compensation, working environment and human skills. Precision and ultra-precision grinding machine are the key to ensure the machining accuracy.

(2) Superabrasive grinding wheel is the main tool for precision and ultra-precision grinding

Superhard grinding is a very thin layer of cutting, grinding depth is very small, requiring abrasive materials with high temperature strength and high temperature pressure, so the use of diamond and cubic boron nitride superhard abrasive; Because of the low requirement on surface roughness, superhard abrasive grinding wheel is used for grinding.

(3) Precision and ultra-precision grinding is a kind of ultra-fine cutting process

Precision and ultra-precision grinding is a type of extremely thin cutting in which grinding is performed inside the crystal and the machining allowance removed is very small and is likely to be comparable to the degree of precision required for the workpiece.

2. Application of precision and ultra-precision grinding

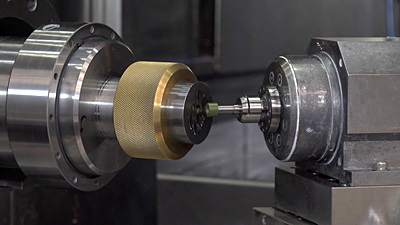

(1) Grinding iron and steel and its alloys and other metal materials, especially hardened steel after quenching and other processing.

(2) Can be used for grinding non-metallic hard and brittle materials, such as ceramics, glass, quartz, semiconductor materials, stone, etc.

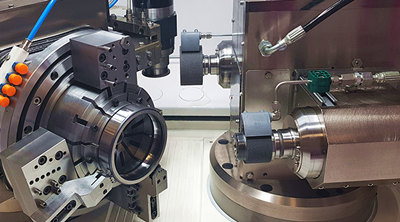

(3) At present, there are mainly external grinding machine, plane grinding machine, internal grinding machine, coordinate grinding machine and other ultra-precision grinding machine, used for ultra-fine grinding outer circle, plane, hole and hole system.

(4) Precision and ultra-precision grinding and its free abrasive processing are complementary.

—–EDITOR: Doris Hu

—–POST: Doris Hu