Application of Laser measurement technology in precision machining process

The precision machining process of grinding machines is often required to achieve very precise dimensional tolerances, geometric tolerances and extremely high surface quality. Most companies usually use their experience to meet these requirements. However, in the process of processing, people have an extremely urgent need for the measurement in the process, especially for the measurement and correction of errors in the process. Laser controlled measurement can significantly improve the stability and yield of the grinding process, which is a perfect, extensive and flexible solution for all kinds of parts.

1. Laser measurement technology integrated into STUDER universal cylindrical grinder

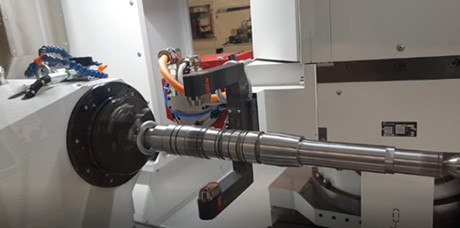

STUDER can draw on more than 10 years of experience with machine-integrated laser measurement technology, which has been evaluated for use in grinding wheel or workpiece measurement tests. This basic research has a tradition in STUDER to ensure that the company is prepared for future production technology trends. The necessary measuring device (see Figure 1) is installed mechanically, similar to our B-axis measuring probe, this situation is not unfamiliar to the operator.

The size of the measuring device can be adjusted according to the diameter of the workpiece. Continuously working through the air nozzle during the measurement process can effectively protect the laser optical components and prevent the coolant in the machine from being damaged;At the same time, the most striking thing is that thousands of measurement points can be generated for evaluation when the workpiece is rotating. This greatly reduces the measurement time and provides users with a non-contact measurement method suitable for precision workpiece processing.

It should also be mentioned thatthis laser measuring device can not only record different diameters on the same workpiece, but also accurately measure intermittent surfaces, such as the diameter of key grooves, longitudinal grooves and gear shaft parts (see figure 2).

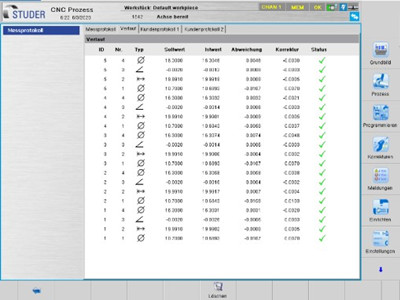

The measurement period can be selected after each machining operation or at the end of the grinding process as required. STUDER software will record the measurement value of each diameter after each measurement cycle (see Figure 3). This process allows the operator to determine the quality of the ground workpiece at a glance.

2. Application examples of laser measurement technology on cutting tools

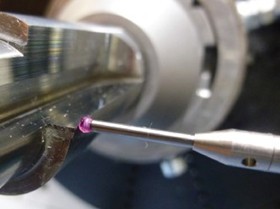

A very effective example of the use of integrated measurement strategies is the complex machining of small batches of tools with PCD cutting edges. The so-called “closed loop process” using a contact measuring device is usually used for this purpose (Figure 4). The cutting edge of the tool is repeatedly measured, ground, measured, etc. Through this measurement, the diameter tolerance can reach +/-1.5 microns, a very good result. Because PCD cutting edges are sometimes sensitive to contact measurement, the demand for non-contact measurement in these applications is increasing.

Based on the measurement difference between the cutting edge diameter and the tool holder in the same measurement plane, laser optics can even determine this diameter when the workpiece is rotating. This is true for most tool machining and has a positive effect on shortening the measurement time.

The strategy of integrating laser measurement technology in machine tools further expands the possible applications of online measurement technology in grinders. Accurate, universal, non-contact measurement technology supports users to improve the efficiency of precision machining.