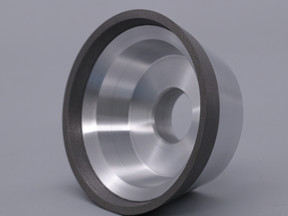

Diamond/CBN Clearance Angle Grinding Wheel for Milling tool

Clearance angle grinding specially for grinding Carbides and steels; Including Drills/End mills/Reamers /Micro drills/Mini end mills/Burrs.

High wheel shape retention

High stock removal

Superior surface quality

Fast cutting speed

By grinding clearance angles and tool flanks on a tool cutter, you reduce the contact area between the tool and the workpiece later on during the drilling or milling process.The clearance angles on the face and circumferential surface of a tool are referred to as the axial and radial clearance angles. These clearance angles provide the tool with a free-cutting property and simultaneously reduce the feed forces when drilling and milling.

Application of clearance grinding wheel

Specially for grinding Carbides and steels; Including Drills/End mills/Reamers /Micro drills/Mini end mills/Burrs.

Advantages of cnc grinding wheels

1. High wheel shape retention

2. High stock removal

3. Superior surface quality

4. Fast cutting speed

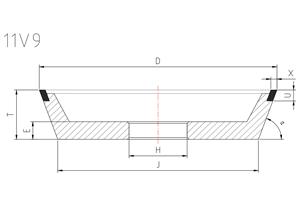

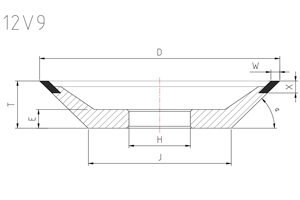

Recommend Wheel

Wheel Bond Material

Resin Bond: For small stock removal and provides perfect finishing when sharpening carbide tools. Widely used for fresh tool manufacturing and re-sharpening process in Milling & Drilling operations.

Hybrid bond: For large stock removal and high feed speed, low machine power;

Available on CNC Tool and cnc grinding wheels for both tooling manufacture and tooling re-sharpening;

| Type | D | T | X | S | Grit Size | ||||

| 11V9 12V9 | mm | Inch | mm | Inch | mm | Inch | diamond | CBN | |

| 75 | 3 | 25-40 | 1-8/5 | 3-10 | 1/8-2/5 | 70̊ 45̊ |

D126 D64 D46 D35 |

B126 B91 B76 B64 |

|

| 100 | 4 | 25-40 | 1-8/5 | 3-10 | 1/8-2/5 | ||||

| 125 | 5 | 25-40 | 1-8/5 | 3-10 | 1/8-2/5 | ||||

Related Products

-

Flute Grinding Wheel for Carbide Round Tools on CNC Machine

Flute Grinding Wheel for Carbide Round Tools on CNC MachineFlute Grinding Wheel for Carbide Round Tools on CNC Machine

-

11V9 Hybrid Diamond Grinding Wheel for Rotary Tools

11V9 Hybrid Diamond Grinding Wheel for Rotary Tools11V9 Hybrid Diamond Grinding Wheel for Rotary Tools

-

Diamond and CBN wheels for grinding carbide and HSS. (such as drill, end mill, reamer)

Diamond and CBN wheels for grinding carbide and HSS. (such as drill, end mill, reamer)Superabrasive diamond grinding wheels for CNC tool grinder

-

11A2 Vitrified Diamond Grinding Wheel for PCD/PCBN Tools

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.