What material can Virtifed CBN grinding wheel process?

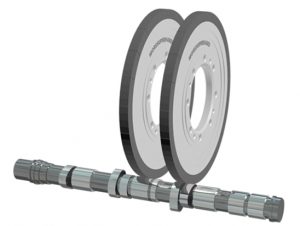

Vitrified bond CBN grinding wheels are increasingly used in the fields of grinding micro-bearings in the inner circle (for magnetic tape, video recorder and office automation equipment), grinding cams or grooves, or honing automotive parts. This is because vitrified CBN grinding wheel or honing strip is different from resin, metal or electroplating bond CBN grinding wheel, it is particularly suitable for the above field of large-scale production needs. This paper mainly discusses the differences of CBN grinding wheel with different bond agents and their grinding effects, enumerate some practical examples of cubic boron nitride grinding tools with vitrified bonding agents and the selection methods of grinding parameters and grinding tools specifications.

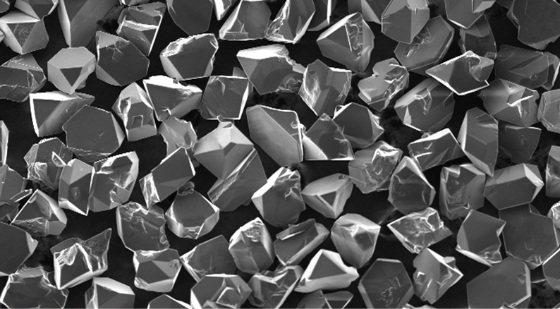

Vitrified bond CBN abrasives can be either pores abrasives or non pores abrasives. The latter uses a similar method to resin, metal bond cubic boron nitride abrasive. Stomatal abrasives are especially suitable for large-scale production processes that require prolonged grinding. The CBN abrasive has good cutting performance, and the coolant can timely wash the workpiece debris away from the pore of the abrasive tool. In addition, the grinding tool can be trimmed with a single point diamond dresser, these are the pores of the vitrified bond cubic boron nitride grinding tool is better than the pores of the resin or metal bond CBN grinding wheel.

However, the electroplating bond cubic boron nitride grinding tool is widely used in fixture grinding and slow feed grinding, but it can not be trimmed; It is suitable for grinding, but can not obtain high workpiece accuracy. In addition, because it has only a single layer of abrasive, abrasive tool service life is short. The vitrified bonded cubic boron nitride abrasive tool is different. It can be trimmed by the way of dressing ordinary abrasive tools, and the number of dressing is very few. This means that the abrasive tool life is longer, machining workpiece accuracy is higher.

Characteristics of vitrified bonded CBN grinding wheel:

The grinding wheel has a porous internal structure, the bond has a strong control force on CBN, cutting sharp, grinding force is small, the grinding wheel keeps high grinding efficiency, avoid workpiece surface burns and micro cracks. The workpiece surface is in the state of compressive stress, which improves the compressive and fatigue strength of the workpiece, and the durability of the workpiece is increased by 10%-30%, while the life of the grinding wheel is 30-100 times longer than that of the corundum grinding wheel. The grinding wheel has high strength and good impact resistance, and the linear speed can reach more than 60m/s.

Materials, workpieces and grinding methods suitable for vitrified bonded cubic boron nitride grinding tools are shown in the following table:

| Machinable material | Workpiece | Grinding method | |

|

Tool steel

|

SKH HSS (M series)

|

Drill bit, tap, end mill, broach, hob mill, tool head | External circular grinding, surface grinding, tool grinding |

| SKS Alloy Steel (T series)

|

Broaching tool ,drill, tap, end mill, broach, hob mill, tool head | Profile grinding | |

| SKS Alloy Steel (0 series)

|

Mold, positioning device |

Internal grinding, surface grinding, cylindrical grinding, jig grinding, centerless grinding

|

|

| SKS Alloy Steel (D series)

|

screw plate

|

||

| SK Carbon Steel (W series)

|

Molds, industrial tools | Internal grinding, surface grinding | |

|

Structural use alloy steel |

SC(Carbon Steel )

|

Camshaft, sewing machine parts | Surface grinding, CAM grinding |

| SGM(4100 series) | Gear (shaft hole), fuel injector, pressure cylinder (air, oil)) | Internal grinding, surface grinding, CAM grinding | |

| SNC(8600 series) | Pressure cylinder (air, oil) shift CAM, sewing machine parts | CAM grinding and honing | |

| SNCM | Crankshaft, mold | Internal grinding | |

| SACM | Vane pump component | Cylindrical grinding | |

| SCr chrome steel(5100series) | Gear (shaft hole) oil pump | CAM grinding | |

|

Bearing Steel

|

SUJ Bearing Steel

(52100) (52100) |

Bearings (for video recorders, cars, etc.) |

Internal grinding, surface grinding |

| Casting steel | SF | Camshaft, compressor parts | Internal grinding, CAM grinding |

|

Superalloy degassed chromium

|

Inconel Renes |

Inconel,Renes (Airplane Part ) |

Surface grinding

|

|

Stainless steel (not heat treated) |

SUS303 |

Measuring instruments, sewing machine parts

|

Surface grinding

|

| Cast iron | FC | All kinds of oil cylinder | Honing |

| Non-ferrous metals | copper alloy | Electrode (EDM) | Surface grinding, flute grinding |

—EDITOR: Doris Hu

—POST:Doris Hu