Model Type of Double-Disc Grinding Machine and Grinding Workpieces

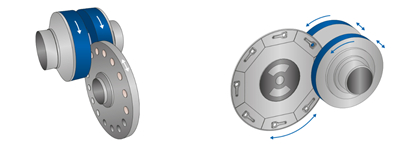

DDG(Double Disc Grinding) machine mainly uses the high speed rotation of grinding wheel to grind the surface of the workpiece to achieve the accuracy. The working principle of different double disc grinding machine is also different.

1. Horizontal spindle double disc grinding machine with rectangular table: Use grinding wheel for peripheral grinding. The worktable reciprocates longitudinally, the grinding wheel rotates vertically, and the lateral feed is realized by the grinding wheel or the worktable.

2. Horizontal spindle double disc grinding machine with round table: Use the grinding wheel for peripheral grinding, the table is associated with rotary motion, and the rest of the working motion is realized by the grinding wheel.

3. Vertical spindle double disc grinding machine with rectangular table: The end face of the grinding wheel is used for grinding, and the table moves longitudinally and reciprocally. The grinding wheel with large diameter also moves vertically in addition to rotation.

4. Vertical spindle double disc grinding machine with round table: Also uses the end face of grinding wheel for grinding. Besides continuous rotation of the round table, it can also realize longitudinal reciprocating motion. The grinding wheel should move vertically in addition to rotation.

Double disc grinder can process metal and non-metal materials such as cast iron, steel, magnetic alloy, aluminum, brass, copper, plastic, ceramics, etc. The workpieces suitable for double face grinding is summarized as follows:

1.The workpiece has a single material composition (there are also many equipments can process double material workpiece)

2.The processing area of the two opposite end faces is almost the same, and the structure is almost the same (at present, there are also many imported equipments and domestic high-end equipments that can process the workpiece with different grinding area of the two end faces)

3. The parallelism of the two opposite faces is better

4. the surface finish and hardness of the two opposite end surfaces are the same

5. The machining allowance and tolerance of the two ends are almost the same

The ideal workpieces of double face grinder are rolling bearing, small and medium ring gear, transmission clutch ring, plate and gasket, hydraulic pump stator and rotor, valve plate, automobile universal joint head, automobile connecting rod, cylinder block and so on.

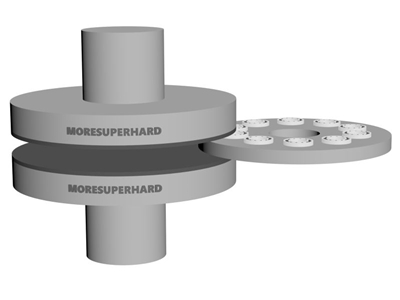

Moresuperhard offers vitrified diamond CBN double disc grinding wheel, and offers a full line of diamond and CBN grinding wheels and dressing stones for fine grinding machines and single and double side lapping systems.

Vitrified diamond grining wheel applied in: grinding the surface, suitable for steel, cast iron, copper, carbide,PCD/PCBN inserts, hard alloy, ceramics, monocrystalline silicon and other processing a full line of diamond and CBN grinding wheels and dressing stones for fine grinding machines and single and double side lapping systems.

—EDITOR: Julia Zhang

—–POST: Doris Hu