How to high precision process bearing?

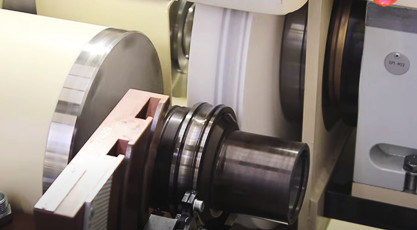

The cylinderical grinding of the bearing ring needs to be processed by centerless grinding machine. Generally speaking, the segmented centerless grinding can achieve very high accuracy. It is mainly divided into coarse grinding, semi-fine grinding, fine grinding. Each stage removes enough margin to ensure that the next grinding stage does not cause problems such as burns or ripple marks. After fine grinding, the product can reach the dimensional precision of finished product. Centerless grinding are also used for machining small size rolling bodies such as rollers and needles.

Grinding of raceway of outer ring and inner diameter of inner ring is an important process in bearing production. The size, quality and precision of the grinding workpiece are greatly improved due to the high hardness, high wear resistance and high chemical inertia of the CBN grinding wheel.

Part of the large size bearing cylinderical grinding and roller will use the infeed grinding or vibration type cylinderical grinding grinding for processing.

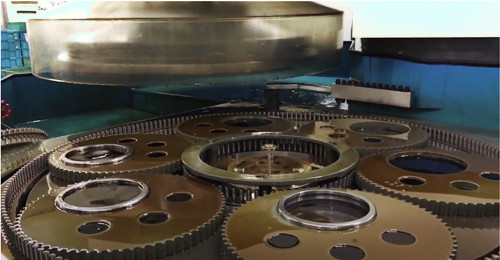

For small and medium size bearing ring end face, it is usually processed by double face grinding. Bearing ring thickness tolerance, flatness, parallelism are ensured by end grinding.

Bearing inner ring inner hole processing and outer ring inner raceway processing can be processed by the inner round mill through the plunge type or shock type. Grinding processes are classified as rough grinding, semi-finish grinding, fine grinding and sparkless grinding because of the different application parameters used. Inner ring processing is called inner hole grinding. Outer ring processing is called outer ring inner raceway grinding. The inner raceway of the outer ring is in direct contact with the rolling body, so the machining accuracy is usually higher than the inner hole of the inner ring.

Throughout the whole bearing manufacturing process, Moresuperhard provides comprehensive bearing processing grinding and polishing solutions: such as bearing inner and outer ring and roller face grinding, centerless grinding, inner and outer ring grinding, bearing inner circle grinding, diamond dresser.

Influence of superfinishing on working performance of rolling bearing:

1. Improve the rotation accuracy of bearings and reduce the vibration and noise of bearings.

2. Improve the bearing capacity of bearings.

3. Improve the lubrication effect of bearings and reduce wear.

4. Reduce the heat when the bearing works

—EDITOR: Doris Hu

—-POST: Doris Hu