How to achieve high precision pinch and peel grinding?

Peel grinding belongs to cylindrical grinding, refers to high speed grinding of cylindrical and non – cylindrical shaft workpieces. When grinding non-cylindrical workpiece, the grinding wheel rotates at a high speed (usually 90-150 m/s) and moves axially at a certain grinding cut depth to achieve axial feed (>100mm/min) and peel the material from the workpiece surface. Because the grinding wheel is very thin, the workpiece speed in the grinding process needs to be large enough to avoid the occurrence of spiral lines.

The precision of cylindrical peel grinding is high, which is suitable for hard materials that can not be processed by traditional processing. peel grinding is a kind of grinding method similar to traditional turning, which is the main competitor of hard turning. It has good flexibility and high grinding efficiency. Peel grinding ensures polished surface finish and unmatched performance to micron level accuracy.

* Automotive industry: Transmission, drive shaft, gear grinding, etc.

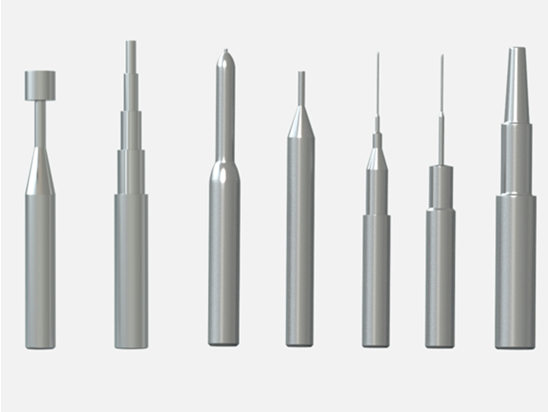

* The two main markets for peel (and squeeze) grinding are grinding parts and cutting tool blanks. Suitable for grinding precision punch, micro pin, die parts and other products.

* It is not only suitable for the preparation of cylindrical blanks, but also for non-circular applications. Especially suitable for flat, threaded and non-circular punch applications.

Advantages of Peeling grinding :

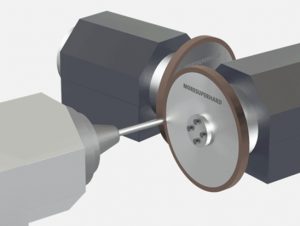

– Complex shapes can be formed without contours. The peel grinding wheel functions like a single point tool under CNC control. As a result, the profile can be easily changed without replacing the grinding wheel.

– One peel grinding wheel can be used for many different operations, whether it is lateral grinding or plunge grinding, tapered section, etc. Often narrow stripping wheels can grind even complex shapes.

– Peel grinding is completed in the range of Ra0.24 to 0.4, which is much faster than traditional grinding due to the fast cutting speed.

– This tends to reduce the force on the part compared to direct plunge-cut grinding. So don’t have to use the same horsepower, and it’s easier to replace parts

– Conventional hard turning cannot achieve a diameter tolerance greater than 10µm.

– By cylindrical peel grinding, part deformation is minimized. It can be roughed and finished at the same time.

– As an alternative to hard turning, improves statistical control, reduces single-piece tool costs, and is a better way to deal with intermittent cutting, such as keyways and slots that are difficult to solve with single-point turning tools.

– The same process was found to be successful for high blank removal applications in hard steels such as 52100 and D2, allowing very short cycle times without burning or cracking surfaces. We found that the high speed CBN peel process has a much lower grinding temperature and a much lower force

– Surface finish quality down to Ra 0.02 mm, accuracy and dimensional consistency in production, with tolerances of only a few microns.

Moresuperhard can provide vitrified/ resin/electroplated CBN grindng wheel for external cylindrical grinding of milling cutters, drills and wire tapping, grooves, flats, threads and chamfers, etc.

Using parameters of cylindrical peel grinding wheel :

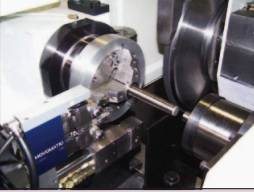

– When choosing a peel grinder, you need overall high stiffness and a good bearing system. Wheel speed should be in the range of 90-140 m/ SEC and RP in the range of 1000 to 10,000.

– Diameter range of grinding workpiece: 0.05-20.0mm.

– Narrow grinding wheels usually 0.25 inch (6.4 mm) or smaller in width for grinding parts.

– Sintered electroplated bonded grinding wheels are recommended. Only about 25% of applications use vitrified-bonded super abrasives grinding wheel. Wheel speeds are usually in the 80-110 m/ sec range.

– Vitrified CBN abrasives for peel grinding have also been shown to be more efficient in hard-to-cut materials such as inconel and soft stainless steel.

Can hard turning replace peel grinding?

The answer should be a resounding “no”.

Both conventional grinding and hard turning will maintain or establish their respective applications in industry according to their inherent advantages and disadvantages. For example, one disadvantage of hard turning is that it cannot reliably maintain very tight diameter tolerances if combined with high Cpk values. The peel grinding wheel cuts the workpiece with a small contact area, similar to the cutting tools on CNC lathes. For this reason, the process combines the advantages of hard turning and grinding: fast metal removal rates combined with precise tolerances, constant Cpk values, and fine surface finish. However, the peel grinding works very well without any back corners!

—EDITOR : Lemon Han/Doris Hu

—-POST: Doris Hu