Double disc grinding wheel to thin optical glass

Whether it’s Apple, Samsung, or Huawei, smartphone screens are getting bigger and bigger, and the majority of smartphone screens are made of optical glass (made by grinding and polishing).

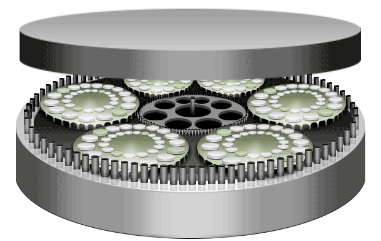

There are two glass thinning processes in the processing process of touch screen, in which the optical glass thinning process generally adopts double end face grinding machine for thinning. It is generally thinned from 1.1mm to about 0.1mm. Because of the hard and brittle characteristics of optical glass, the processing efficiency is very low in regrinding process.

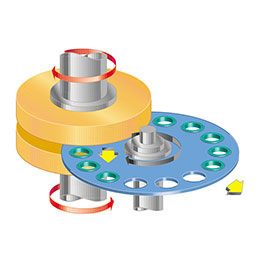

The new mobile phone glass panel thinning process combined with the original two thinning process for one time, using strong grinding, a grinding process is completed, and can realize automatic loading and unloading, the double end grinding machine grinding using rotary through grinding mode, because the glass material hardness is high. Brittle, so a well-matched grinding wheel is the key. Such as strong grinding force workpiece easily broken, small grinding force small removal.

The new mobile phone glass panel double end grinding machine grinding process advantages:

1. Strong grinding, high efficiency of double face grinding

2. Workpiece thickness and size are well controlled

3. Double face grinder can realize automatic loading and unloading, production line production

More SuperHard company offers a full series of diamond and CBN grinding wheels and dressing stones for fine grinding machines and single and double side lapping systems. Our vitrified diamond and CBN grinding discs have high grinding efficiency, high wear resistance and abrasive consumption, good surface quality and flatness of the workpiece.

—EDITOR: Doris Hu

—POST: Doris Hu