Diamond polishing film for Handheld Air-Operated Crankshaft Polisher

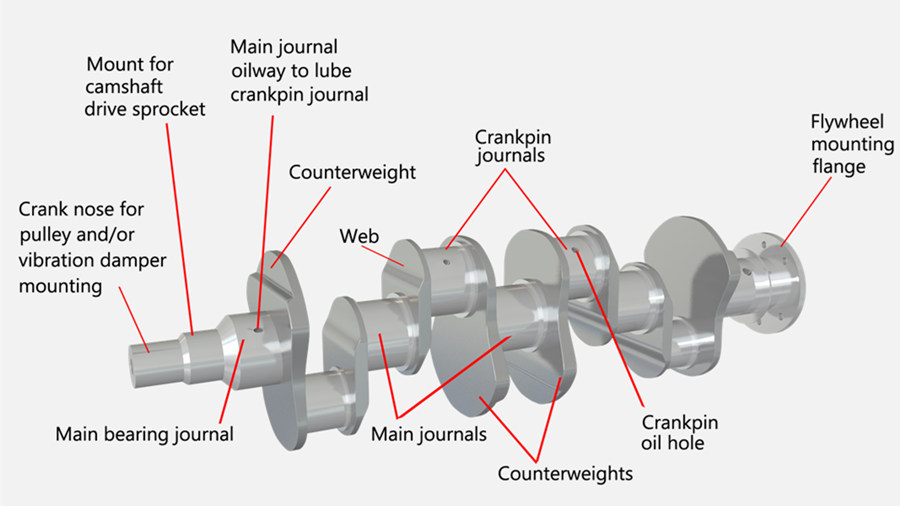

Crankshaft is the most critical part of the engine, so its precision is very high. Crankshaft surface requirements are higher, generally need to go through grinding and polishing process. The general contour is ensured by rough grinding of grinding wheel, and the surface roughness is ensured by precision diamomd polishing film.

The final finishing steps of camshaft and crankshaft polishing requires precision and extremely tight tolerances. Norton Finium microfinishing films deliver a precise finish every time without the worry of imperfections.

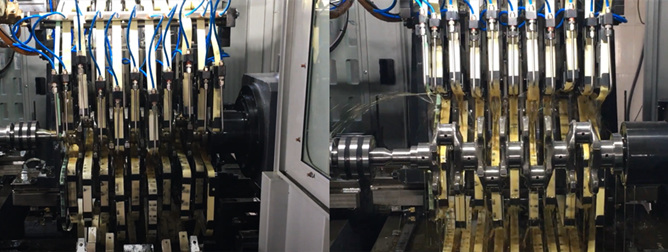

The grinding/polishing of the crankshaft uses a thin film backed polishing belt. This material is completely flat, which ensures the accuracy of the grinding surface. Because the crankshaft needs to be polished to the R Angle, the grinding and polishing of the crankshaft requires the use of serrated polishing tape.

Crankshaft Polisher

Our air-operated crankshaft polishers feature high torque output air motors that help you handle the toughest jobs. Since the polisher is pneumatic, there is no need to worry about buying a replacement motor due to abrasive dust that builds up on the armature and brush. Thus removing quickly the minor surface faults left by the grinding operation, without altering the shape of the journals. And extremely low weight and by its high maneuverability. This will greatly improve the pefformance features of the machined surfaces, for example more bearing capacity, lower friction coefficient, longer life.

Polishing belts size: 1 “x 64, Grit size 240#, 320#, 400#

If you have any requirements, you can contact Sarah by email sarah@moresuperhard.com to communicate in detail.

—EDITOR: Sarah Shi/ Doris Hu

—POST:Doris Hu