Diamond Dicing Blade for DFN Semiconductor packaging

01 Principle of Diamond Dicing Blade for DFN

The Diamond dicing blade is mounted on the soft blade flange of the cutting equipment’s spindle. Under high-speed rotation of the spindle at RPM 20,000 to 30,000, the workpiece to be cut are broken by fracturing way and the chip pocket to remove the chips in time to ensure the processing quality.

02 Processing

| Machine | DICCO 350 | Diamond dicing blade | 1A8 SD240

58×0.3×40 |

| Work piece | DFN 2X2 | Spindle speed | 25000RPM |

| Size | 256x70mm | DIE size | 2.0×2.0mm |

| Cooling water temperature | 12±2° | Cooling water flow | 1.5L/m |

| Work piece material | Cooper + epoxy resin | Feed speed | 40mm/s |

| Cut mode | Single shaft cut through | Cutting time | 15minutes |

| Processing way | UV film cut | Cutting height | 0.1mm |

| Work piece thickness | 0.75mm | Film thickness | 0.15mm |

| Cutting width | 0.3mm | Cutting life | 2000m |

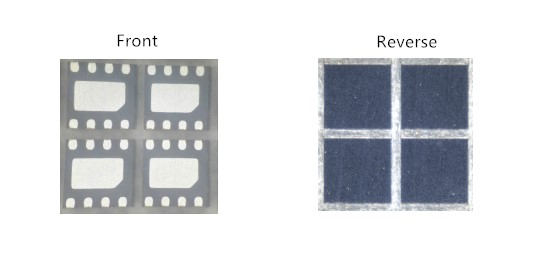

03 Result

No burr, fracture and metal lamination were examined under 40 power microscope.